As a common packaging method, candy cans are not only convenient for storage and transportation, but also protect the quality of candy. Today, candy cans on the market are rich in materials, mainly including tinplate, aluminum alloy, plastic and other materials. Tinplate plays an important role in the production of candy cans due to its unique protective performance and appearance advantages. This article will explore in depth the main material composition of candy cans and the proportion of tinplate used.

What materials are candy cans mainly made of?

1. Tinplate: Common material for candy cans

Tinplate is the most common material in the current production of candy cans. Tinplate is essentially a tin-plated thin steel plate with good oxidation resistance and corrosion resistance. Because the surface of tinplate is coated with a layer of tin, it can effectively isolate air and moisture to prevent candy from getting damp and deteriorating. In addition, tinplate has good hardness and compressive strength, and can withstand the external force impact of candy during transportation and storage.

2. Aluminum alloy: The lightweight choice for candy cans

Aluminum alloy is also one of the common materials for candy cans. Compared with tinplate, aluminum alloy has a lower density, so candy cans are lighter and easier to carry. In addition, aluminum alloy has good corrosion resistance and is easy to shape, so it can be used to make some candy cans with complex shapes. However, due to the relatively high cost of aluminum alloy and its lower hardness compared to tinplate, its application ratio in the production of most candy cans is relatively small.

3. Plastic: An economical choice for candy cans

Plastic cans are also widely used in candy packaging because of their low cost and simple manufacturing process. However, plastic has strong air permeability and is difficult to keep out moisture for a long time, and its appearance is often not as good as that of metal cans. Therefore, plastic cans are mainly used in some low-cost, short-term storage candy packaging.

Why is the proportion of tinplate in candy cans higher?

1. Tinplate has excellent moisture and oxidation resistance

One of the important purposes of candy packaging is to keep candy dry and fresh to avoid moisture and deterioration. Tinplate is coated with a layer of tin, which has extremely strong oxidation resistance and moisture resistance. This feature makes tinplate an ideal choice for candy can production, especially in candy products with a long storage period, where its protective performance is particularly important. Therefore, compared with other materials, tinplate cans can better protect the taste and quality of candy.

2. The hardness advantage of tinplate brings stronger pressure resistance

Candy cans need to withstand certain extrusion and impact during transportation and sales. Tinplate has high hardness and pressure resistance, which can effectively prevent the deformation of the can body. Compared with aluminum alloy and plastic, candy cans made of tinplate have higher impact resistance, which can avoid the risk of damage and deterioration of cans due to damage to the can body during storage.

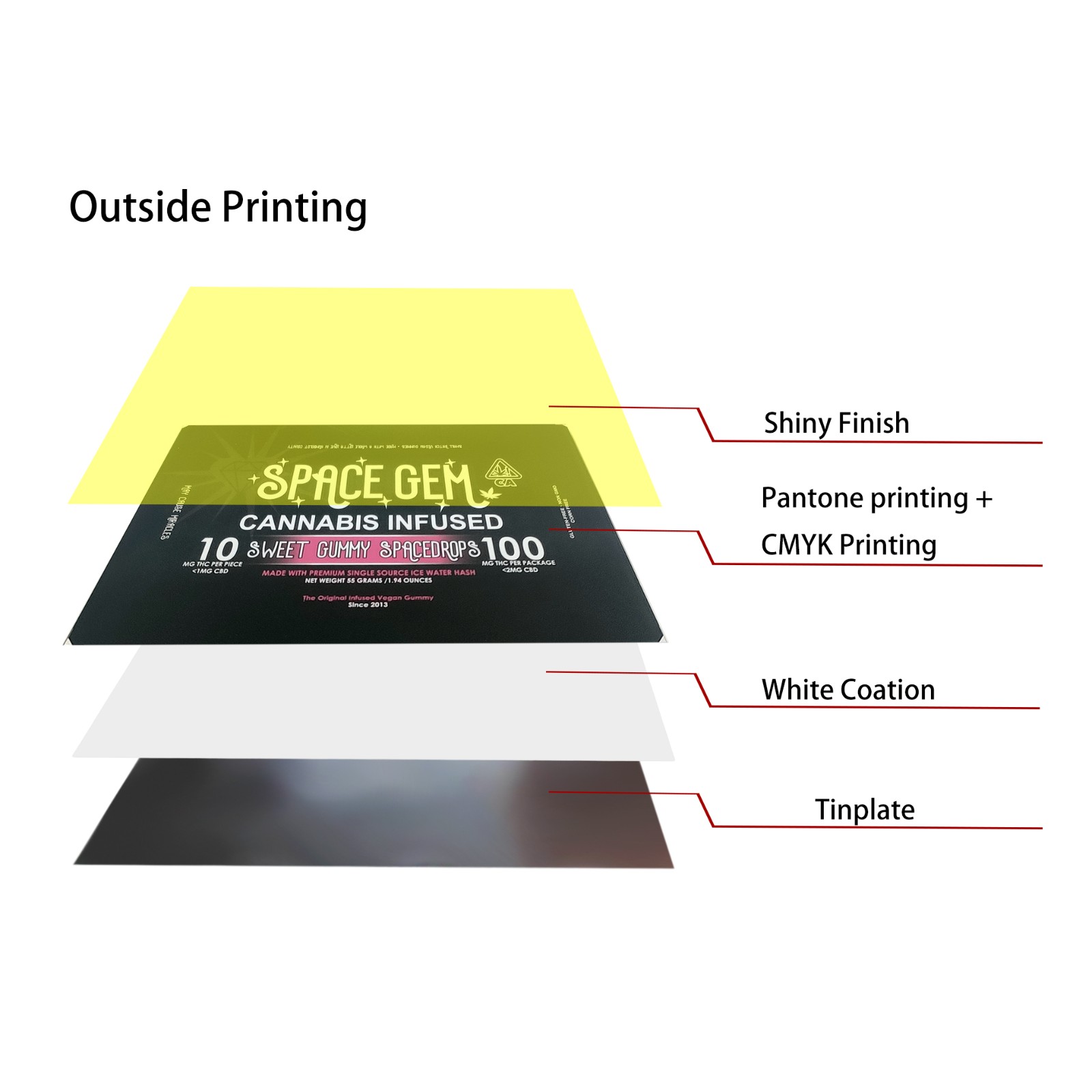

3. Tinplate cans are easy to print and have stronger aesthetics

The surface of tinplate is relatively smooth, which is very suitable for printing and can achieve high-quality pattern printing. This makes the tinplate candy can be more beautiful in appearance, and the color and pattern are more expressive. Compared with aluminum alloy and plastic, the printing effect of tinplate cans is more delicate, which can better attract the attention of consumers.

How to make tinplate candy cans?

1. What steps are required to make tinplate candy cans?

The production of tinplate candy cans requires a series of complex processes such as cutting, stamping, forming, and welding. First, the tinplate sheet is cut according to the size of the candy can, and then it is formed by stamping equipment to form the basic shape of the candy can. The formed can body is then welded to ensure the sealing of the can body. Finally, the surface of the candy can is painted, printed and dried to give it a beautiful appearance.

2. Why does the surface of the tinplate candy can be painted?

The surface of tinplate is prone to oxidation and rust. In order to enhance its corrosion resistance, a layer of protective paint is usually sprayed on the inner and outer surfaces of the can body. In particular, the inner protective paint of the candy can not only prevent adverse reactions caused by direct contact with the candy, but also ensure food-grade safety standards to avoid the release of harmful substances.

3. How to ensure the sealing of the tinplate candy can?

The sealing of the candy can directly affects its moisture-proof performance and the shelf life of the candy. In order to ensure the sealing effect, a sealing rubber ring is usually installed between the can body and the lid during the production process to ensure that the can body and the lid fit tightly, thereby achieving a good sealing effect. A tinplate candy can with good sealing can not only effectively isolate the air, but also prevent external moisture from entering, ensuring the quality and taste of the candy.

How long is the service life of a tinplate candy can?

1. How long is the service life of a tinplate candy can usually be?

Due to its good protective performance and high hardness, the service life of a tinplate candy can usually reach many years under normal storage and use conditions. As long as the surface coating is not damaged, the tinplate can can maintain its moisture-proof and anti-corrosion effects for a long time, and is particularly suitable for long-term storage of dry foods such as candy.

2. Does the external environment have a big impact on the service life of tinplate cans?

The humidity, temperature and acidity and alkalinity of the external environment have a certain impact on the service life of tinplate cans. Although tinplate itself has good anti-corrosion properties, in a humid, high temperature or high pH environment, the tinplate surface coating may age or fall off, thereby affecting its protective effect. Therefore, when storing tinplate candy cans in a humid environment, it is necessary to keep the environment dry to extend its service life.

3. Does the tinplate candy can require special maintenance?

Normally, tinplate candy cans do not require special maintenance, but they need to avoid contact with acidic or alkaline substances to avoid damage to the surface coating. In addition, try to avoid placing tinplate cans in direct sunlight. The ultraviolet rays in the sun may accelerate the aging of the coating, thereby affecting the service life of the can.

How environmentally friendly are tinplate candy cans?

1. Can tinplate candy cans be recycled?

Tinplate is a recyclable and environmentally friendly material, and the candy cans made of it can be recycled after use. Recycled tinplate can be reprocessed into new steel or tinplate products, which helps to reduce the waste of resources and pollution to the environment. Compared with plastic candy cans, tinplate cans have a higher recycling rate and are more in line with environmental protection requirements.

2. Is there a difference in the quality of recycled tinplate candy cans?

After refining, the quality of recycled tinplate can reach the same standard as that of newly produced tinplate materials. Therefore, candy cans made of recycled tinplate will not have obvious differences in quality, and can still achieve good protection effects. Candy cans made from recycled tinplate not only meet the requirements of green environmental protection, but also effectively reduce production costs.

3. What are the environmental advantages of tinplate candy cans compared with other materials?

Compared with plastics and aluminum alloys, the recycling cost of tinplate is lower, and the recycling process is relatively mature, and it is not easy to pollute the environment. In addition, tinplate candy cans do not release harmful substances during use and are harmless to human health. This makes tinplate candy cans relatively superior in terms of environmental protection and safety, and an ideal choice for candy packaging.

Premium Quality Metal Packaging at Wholesale Prices

Looking for high-quality metal packaging at wholesale prices? Foshan Dekai Metal Packaging Co., Ltd. provides top-tier aerosol cans, tinplates, and custom-printed solutions for businesses worldwide. With a focus on precision manufacturing and excellent customer service, we deliver reliable products that meet your packaging needs. Our advanced automated production lines ensure efficiency, while our affordable pricing helps you stay within budget.