As an indispensable packaging solution in modern industry and daily life, metal aerosol cans are widely used in chemicals, personal care products, food, household cleaners, medicines and other fields. Especially in the chemical industry, refillable metal aerosol cans are favored for their durability, high sealing and environmental protection. This article will introduce the characteristics, advantages and wholesale mode of customizable metal aerosol cans in detail to help customers gain a deeper understanding of products and services in this field.

Product Overview: Core Features of High-Performance Metal Aerosol Cans

Metal aerosol cans are made of high-quality tinplate (tin-plated iron) as the main material and refined through multiple processes. Its design and performance parameters are as follows:

● Specifications and sizes: A variety of diameters are available, including 45mm, 52mm, 57mm, 60mm, 65mm, and the height range can be customized from 100mm to 300mm according to customer needs.

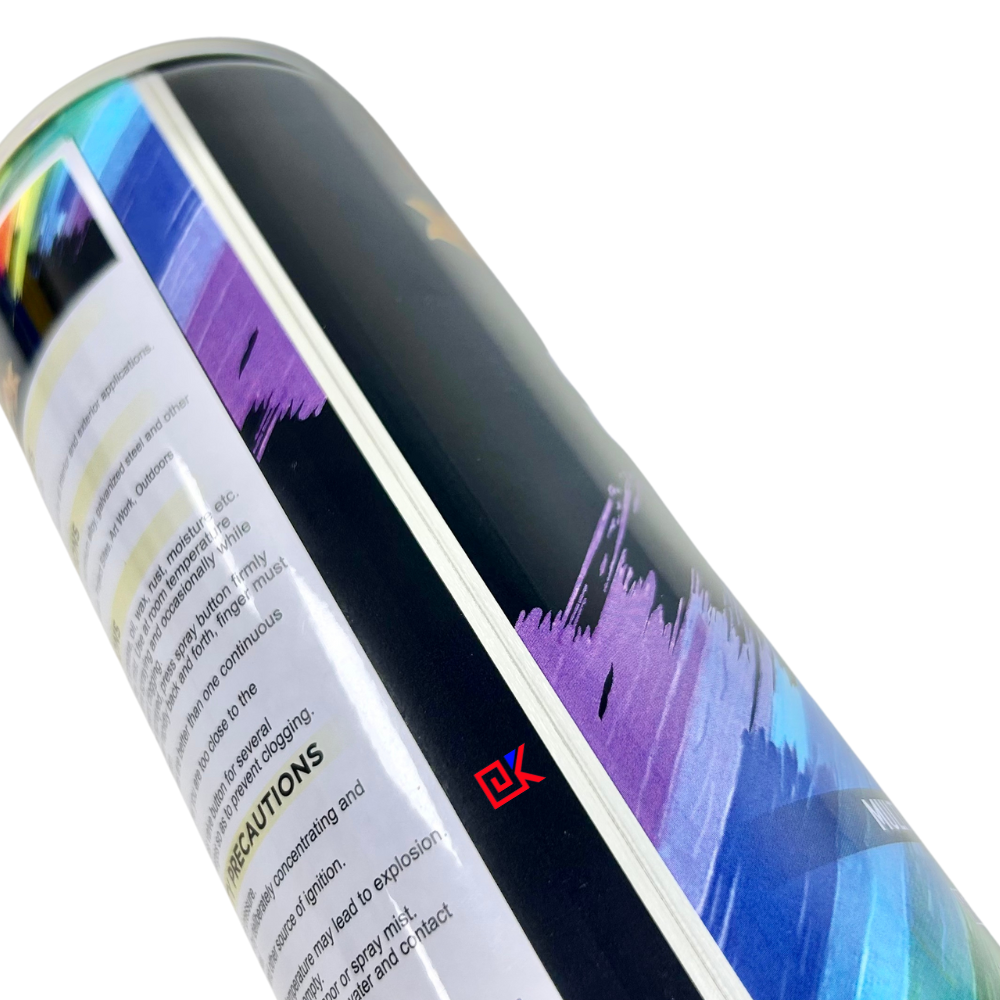

● Materials and processes: The can body is made of tinplate, and the surface treatment adopts high-quality offset printing technology, which can be customized in CMYK or PANTONE colors according to customer needs.

● Surface finish: three options of glossy varnish, matte varnish or silver iron to meet the packaging needs of different products and brands.

Printing and logo: support the printing customization of customer LOGO to ensure the brand display effect, while providing clear pattern and text printing.

● Sealing performance: use pump sprayer as sealing component to ensure high sealing and prevent leakage of contents.

● Environmentally friendly design: support refilling, extend the service life of the can body, and reduce disposable packaging waste.

● Performance test: bursting pressure ≥1.4MPa, deformation pressure ≥1.2MPa, to ensure the reliability and safety of the product under various conditions.

The metal aerosol can has passed ISO 9001:2008 quality certification and GB13042-2008 standard certification, complies with international requirements such as RoHS and DOT, and provides global customers with safe and high-quality product guarantees.

Customized service: meet the personalized needs of customers

In the fiercely competitive market environment, customizable services have become one of the important means for manufacturers to attract customers. The customized design of metal aerosol cans can not only meet the packaging needs of the brand, but also play an important role in marketing.

1. Size customization

Different products have different requirements for the size of packaging containers. For example, chemicals may require large-capacity cans, while personal care products prefer small and portable designs. Manufacturers support customers to choose the diameter and height of the can according to specific uses and flexibly adjust the capacity.

2. Color and pattern

Appearance design is one of the important factors for products to attract consumers' attention. By using CMYK or PANTONE color offset printing, customers can customize brand logos, slogans, patterns, etc. on metal aerosol cans to create unique packaging and improve product recognition.

3. Surface treatment

According to different market positioning and user preferences, you can choose glossy varnish, matte varnish or silver iron effect to add texture and uniqueness to metal aerosol cans.

4. Logo and text

The manufacturer provides advanced offset printing technology to ensure the clarity and stability of LOGO, text and other printed content, so that this metal aerosol can can maintain its original appearance after long-term use.

Wholesale and supply: efficient service and cost advantage

As a professional manufacturer of metal aerosol cans, we provide a flexible wholesale model to meet the purchasing needs of different customers:

● Wholesale price: set preferential prices according to the purchase volume. The larger the order volume, the lower the unit price. For example, the unit price of 100,000 to 999,999 pieces is US$0.1; when the purchase volume reaches more than 1,000,000 pieces, the unit price drops to US$0.09, saving costs for customers.

● Production capacity: relying on advanced automated production equipment and efficient process flow, the annual output can reach tens of millions of pieces, fully guaranteeing the timely delivery of customer orders.

● Quality inspection: each batch of metal aerosol cans undergoes rigorous performance testing and quality inspection to ensure that the products meet customer and international standards.

Through wholesale procurement, customers can not only get more competitive prices, but also enjoy the manufacturer's comprehensive services, including design support, quick response and after-sales guarantee.

Environmental protection and sustainable development: the advantages of metal aerosol cans

Metal aerosol cans have gradually become the representative of environmentally friendly packaging due to their refillable and recyclable characteristics. The following are the main advantages of this product in terms of environmental protection:

Refillable

Compared with disposable packaging, refillable metal aerosol cans extend the product life cycle, reduce resource waste, and reduce the packaging costs of enterprises.

Recyclability

As a metal material with a high recycling rate, tinplate can be directly put into the recycling system after use and used to make new metal products, further reducing environmental pollution.

Reduce carbon footprint

By promoting refillable metal aerosol cans, companies can significantly reduce carbon emissions generated during production and transportation, and contribute to environmental protection.

Industrial application: ideal choice in the field of chemicals

In the chemical industry, metal aerosol cans are an ideal packaging solution for various chemicals due to their corrosion resistance, sealing and high strength:

● Solvents and detergents: High sealing and pressure resistance ensure that chemical solvents will not leak or evaporate, meeting the packaging needs of industrial and household detergents.

● Sprays: Through the pump spray design, the spray volume can be accurately controlled, and it is widely used in pesticides, rust removers, lubricants, etc.

● Special chemicals: For highly corrosive chemicals, metal aerosol cans provide additional protective coatings to effectively protect the stability of the can and its contents.

Purchasing Guide: How to Choose High-Quality Metal Aerosol Cans

When purchasing metal aerosol cans, customers need to focus on the following points:

1. Material and process: Ensure that the can is made of high-quality tinplate and the surface treatment process meets international standards.

2. Sealing: Check whether the connection between the can and the pump spray assembly is tight to prevent leakage of the contents.

3. Certification and standards: Choose products that have passed ISO, RoHS, DOT and other certifications to ensure quality and safety.

4. Price and service: Compare the wholesale prices and service content of different manufacturers, and give priority to manufacturers that provide customized support.

At DKtinplate, we pride ourselves on being a leading supplier of tinplate packaging and aerosol cans in China. Our factory is equipped with the latest FUJI printing lines and high-speed production equipment, ensuring top-notch quality and cost efficiency. We specialize in wholesale orders, custom packaging designs, and discount pricing to meet the diverse needs of our global customers. Contact DKtinplate for affordable prices, tailored quotes, and high-quality solutions for your packaging business.