As a packaging material widely used in food, cosmetics, chemicals and other fields, the environmental protection of tinplate has attracted much attention. Tinplate is a tin-plated steel plate with excellent corrosion resistance, strength and sealing, but how environmentally friendly is it? What is the impact of tinplate packaging on the environment during production, use and post-disposal? This article will explore the environmental protection characteristics of tinplate packaging and its impact on the environment from multiple aspects.

What are the characteristics of tinplate packaging?

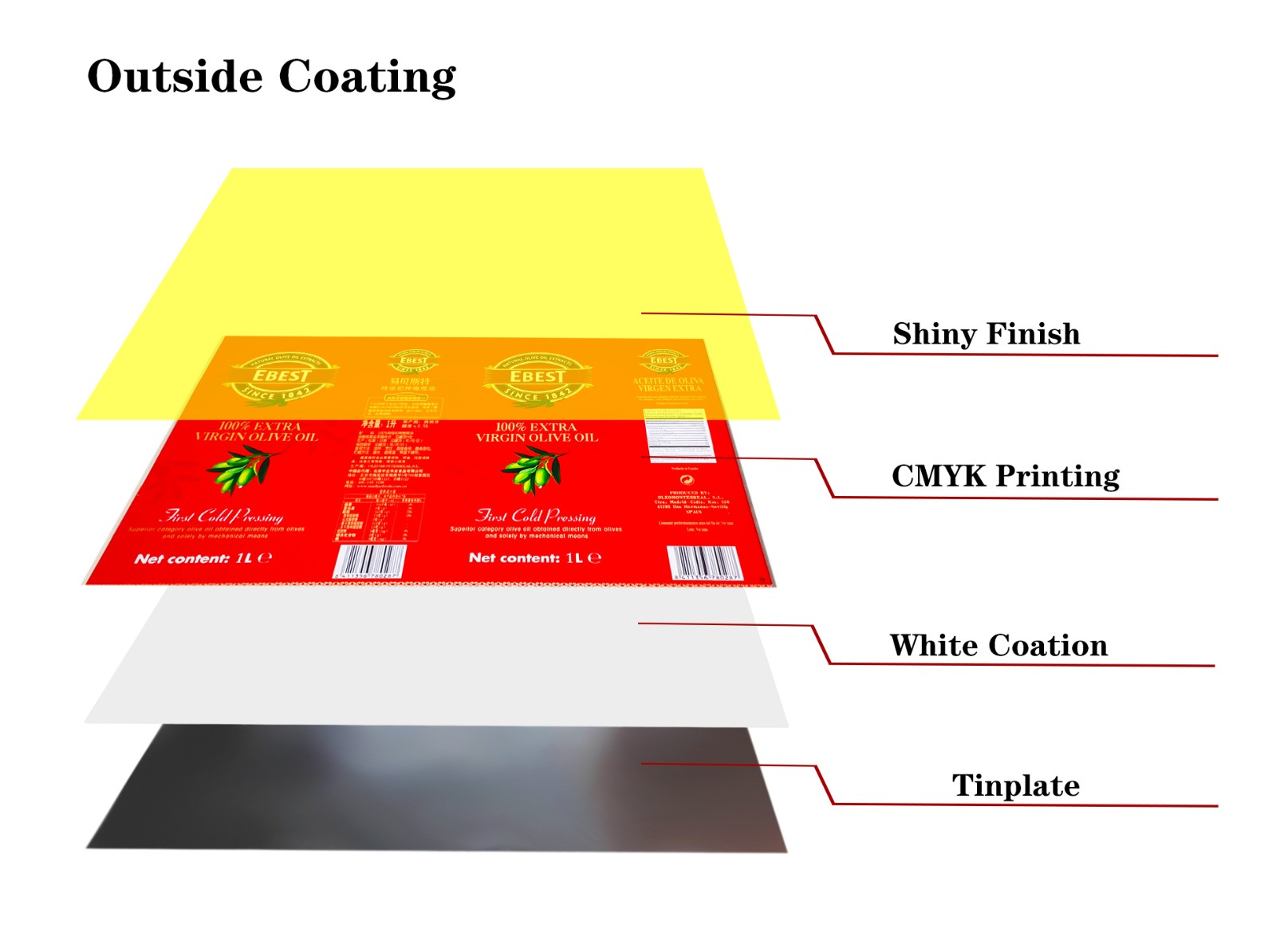

Before discussing the environmental protection of tinplate packaging, it is necessary to understand the basic characteristics of tinplate. Tinplate is essentially a low-carbon steel plate with a layer of tin on its surface through electroplating or hot-dip coating. The main function of this layer of tin is to prevent iron oxidation and rust, enhance the corrosion resistance of the material, and also improve its processability and appearance.

Tinplate packaging is widely used in modern society, mainly for food cans, beverage cans, aerosol cans, cosmetic containers, etc. The strength and plasticity of tinplate packaging materials make it an ideal packaging material, which can not only provide good protection, but also realize complex processing such as stretching and forming.

Production and environmental protection of tinplate packaging

Impact on the environment during the production process

The production process of tinplate includes steel smelting, rolling, tin plating and other processes. The smelting of steel requires a lot of energy and emits a certain amount of greenhouse gases such as carbon dioxide. Chemical substances are also used in the tin plating process. Therefore, in the production stage, the impact of tinplate on the environment is mainly concentrated on resource consumption and pollutant emissions.

Nevertheless, compared with other metal packaging materials such as aluminum, tinplate packaging has relatively low energy and resource consumption in its production process. Because the raw material of tinplate, steel, is abundant in reserves and relatively low in price on the earth, the smelting technology is mature, and modern technology can be used to reduce energy consumption and emissions. In addition, with the development of environmental protection technology, steel production enterprises have made significant progress in reducing emissions, recycling water resources, and reducing energy consumption, which has improved the environmental performance of tinplate as a whole.

Utilization of renewable resources

One of the biggest environmental advantages of tinplate is its recyclability. As a metal material, tinplate can be recycled and reused many times without affecting its physical properties. Recycled tinplate materials can be melted to make steel and continue to be used to produce new products. Therefore, in the cycle of resource utilization, tinplate has a great advantage in reducing resource waste and saving energy.

Globally, the recycling system of metal packaging materials has been relatively complete, especially in developed countries, where the recycling rate of tinplate packaging is very high. Through recycling and reuse, the environmental burden of tinplate can be significantly reduced.

The use and environmental protection of tinplate packaging

Durability and waste reduction of tinplate packaging

Tinplate has high strength and durability, and can effectively protect the contents of the package from the influence of the external environment, such as oxygen, moisture, light, etc. Especially in the packaging of food and cosmetics, the sealing and antioxidant properties of tinplate make it an ideal choice, extending the shelf life of the product.

The high durability of tinplate packaging means that it is not easy to be damaged during use, reducing the waste of resources caused by packaging damage. During transportation, tinplate packaging can withstand external forces such as extrusion and collision, and will not easily break or deform, which also reduces the risk of damage and waste of items.

Guarantee of food safety

The tin-plated layer of tinplate not only provides protection, but also prevents direct contact between food and iron materials, avoiding metal contamination of food. Compared with plastic packaging, tinplate does not contain harmful chemicals, such as bisphenol A (BPA), and does not produce microplastic pollution. Therefore, tinplate packaging is widely used in the food industry, which not only effectively preserves food quality, but also reduces consumers' concerns about health hazards.

In addition, the chemical properties of tinplate packaging materials are stable and will not release harmful gases in high temperature environments, so it is also often used for packaging in special scenarios such as aerosol cans and high-pressure tanks.

Disposal and recycling of tinplate packaging

Recyclability of tinplate

One of the major environmental advantages of tinplate packaging is its high recycling rate. As a metal material, tinplate can be almost 100% recycled and reused. Through smelting and reprocessing, discarded tinplate packaging can be turned into new steel products and continue to be put into use. Recycling tinplate can not only reduce dependence on natural resources, but also significantly reduce energy consumption. Compared with making new steel, the energy consumption of using recycled steel is reduced by more than 75%, and greenhouse gas emissions are also significantly reduced.

It is worth noting that the recycling of tinplate does not require a complex separation process like some materials (such as plastics). Since tinplate is a metal, it can be separated from waste by simple processes such as magnetic separation, which makes its recycling efficiency higher.

Reduce the burden of landfill and incineration

As environmental pressure increases, the negative impact of landfill and incineration on the environment has received more and more attention. Many non-degradable plastics and composite materials produce toxic and harmful gases when incinerated, or cannot be degraded after being buried underground for decades, causing serious pollution to the environment.

In contrast, tinplate packaging has a high recycling rate and can effectively reduce the pressure of landfill and incineration. Even if it is not recycled, tinplate packaging decomposes faster than plastic materials in the natural environment, reducing the long-term impact on the environment.

Environmental challenges of tinplate packaging

Although tinplate packaging has demonstrated its environmental advantages in many aspects, it is not completely without problems. The following are the challenges that tinplate packaging faces in terms of environmental protection:

Energy consumption issues

Although tinplate packaging materials are recyclable and the energy consumption during the recycling process is low, its production still requires a lot of energy. Steel smelting and tinning processes involve high-temperature treatment, and the energy consumption and carbon emissions in the process are issues that cannot be ignored. Therefore, how to further optimize the production process and reduce energy consumption and environmental pollution is a direction that tinplate manufacturers need to continue to explore.

The soundness of the recycling system

Although tinplate packaging has high recyclability, the realization of its environmental benefits depends largely on a sound recycling system. In some developing countries and regions, the waste recycling system is not sound, resulting in a large amount of recyclable materials being landfilled or incinerated, and cannot be recycled. In addition, consumers' environmental awareness and the habit of sorting garbage also have an important impact on the recycling efficiency of tinplate packaging.

Tinning layer treatment

The tinning layer on the surface of tinplate is an important part of its anti-corrosion, but the mining and refining of tin may bring certain environmental problems. In addition, how to treat the tinning layer when tinplate packaging is recycled and reused is also a technical problem. The tin layer needs to be removed or refined before recycling, otherwise it may affect the quality of the recycled steel. Therefore, the treatment process of the tin layer during recycling needs to be further improved to reduce resource waste and environmental pollution.

Foshan Dekai Metal Packaging Co., Ltd. is a leading factory specializing in tinplate packaging and aerosol cans, serving businesses across various industries. Our modern production facility in Foshan is equipped with high-speed equipment and FUJI printing lines, ensuring excellent efficiency and product quality. We work closely with our clients to design and deliver packaging solutions that align with their unique needs. Whether you're seeking affordable wholesale deals or innovative designs, our team is dedicated to helping your business succeed. Contact us for competitive prices and detailed quotes.