Among modern packaging materials, tinplate packaging cans are widely used in food, chemical industry, medicine and other fields due to their excellent sealing, strength and processability. However, in related fields such as industrial electricity, materials science and production safety management, the question of whether tinplate packaging cans are conductive often causes controversy or confusion.

This article will focus on the core question of "Is tinplate packaging can a conductor or a non-conductor?" and elaborate on the material composition, structural characteristics, electrical analysis and other aspects, striving to give a clear and professional conclusion through scientific and rigorous logic.

What is tinplate packaging can?

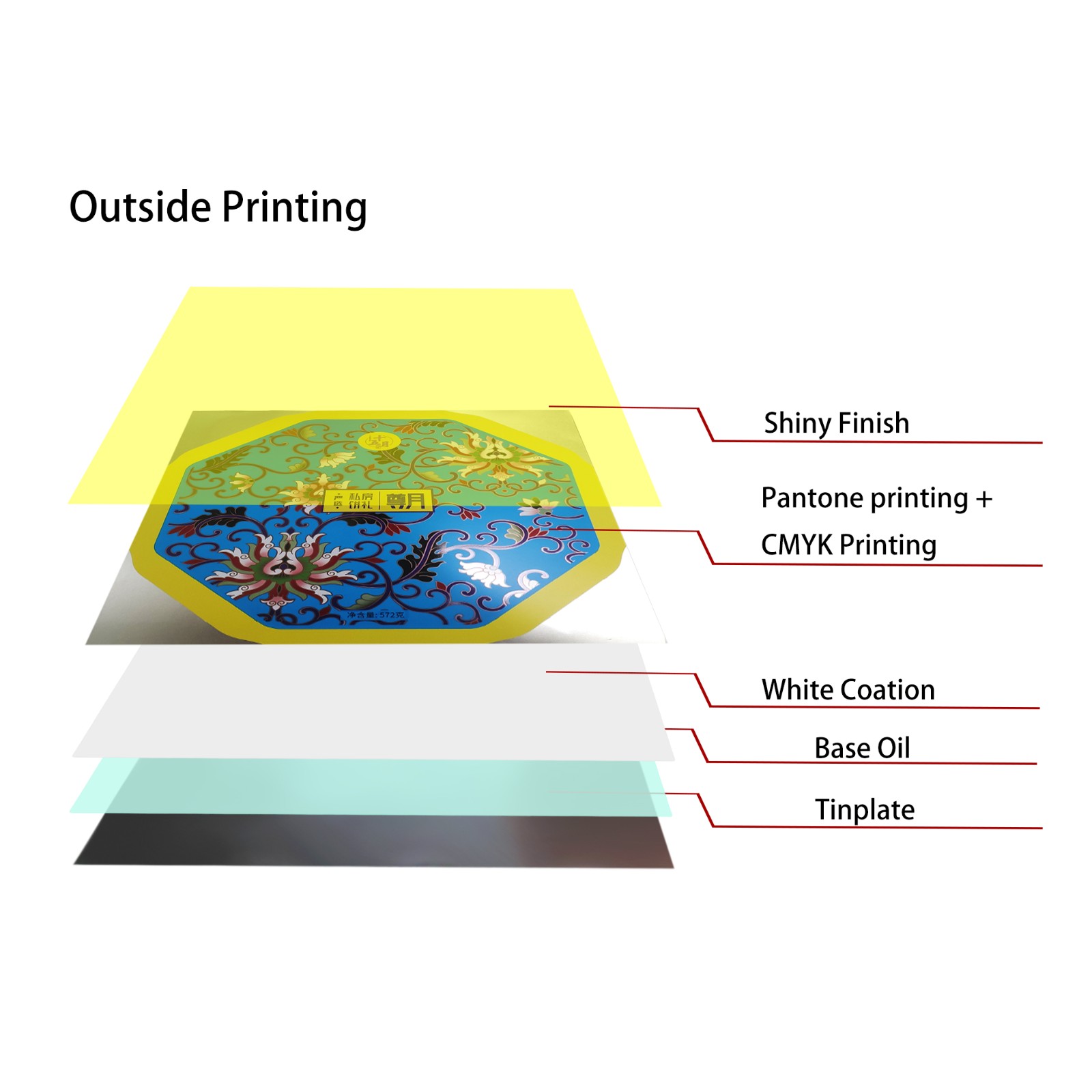

Tinplate, in English, is a composite material with a layer of metal tin coated on the surface of a low-carbon steel plate (generally a cold-rolled steel plate). Tinplate packaging cans are usually made of tinplate plates, and are made into sealed containers with specific geometric structures through stamping, welding, painting, printing and other processes for containing solids, liquids or gases.

The main components of tinplate packaging cans include:

·Base material: cold-rolled low-carbon steel plate, a metal material with extremely low carbon content, with good ductility and strength;

·Coating: a layer of metal tin coated on the surface, usually achieved by electroplating or hot-dip plating, the purpose is to prevent the steel plate from rusting;

·Protective layer: In order to enhance corrosion resistance and aesthetics, a layer of organic coating (such as epoxy resin or polyester coating) is also sprayed on the inner and outer surfaces;

·Structural connection: including welds, folding edges, sealing and other parts, involving metal heat treatment and mechanical processing technology.

Among these components, except for organic coatings, which are insulating materials, the rest are mainly composed of metal elements. Based on this, the conductivity of tinplate packaging cans must be scientifically analyzed from the material itself.

Conductors and non-conductors: What do they mean?

In physics and materials science, conductors refer to materials that can conduct electric current freely. Its essential feature is the presence of a large number of freely movable charge carriers (usually free electrons). When a potential difference is applied to both ends of the material, these carriers will move in a directional manner under the action of the electric field, thereby forming an electric current.

In contrast, non-conductors (also known as insulators) refer to materials that have almost no freely movable carriers, and even if an external voltage is applied, it is almost impossible to form an effective current. For example, rubber, ceramics, glass and other typical insulators.

Whether a material is a conductor or a non-conductor is based on its conductivity (Conductivity) or resistivity (Resistivity). Metal materials usually have extremely high conductivity, while non-metallic materials are mostly insulators with extremely low conductivity.

Electrical properties of the main components of tinplate packaging cans

1. Conductivity of cold-rolled low-carbon steel substrate

Cold-rolled low-carbon steel is an iron-based alloy, with iron as the main element, supplemented by trace carbon (usually between 0.05%-0.25%), and very few other impurity elements. Iron is a typical good conductor with a resistivity of about 9.71×10−8Ω⋅m. Although low-carbon steel varies slightly due to impurity content, its overall conductivity is still quite high, and it is a high-quality conductor material.

2. Conductivity of metal tin coating

Metal tin (Sn) is a soft silver-white metal at room temperature with good ductility and chemical stability. Its resistivity is about 1.09×10−7Ω⋅m, which is slightly higher than copper and silver, but still in the range of typical metal conductors. The presence of tin will not only not weaken the conductivity of the steel plate, but also protect the continuity of the conductive layer due to its uniform coverage.

3. Insulation effect of organic coating

In practical applications, in order to prevent food or chemicals from directly contacting the metal and causing corrosion reactions or contamination, the inner surface of tinplate packaging cans is often sprayed with an organic protective layer, such as epoxy resin or polyester coating. This type of coating has extremely high resistivity and is indeed a non-conductor.

However, the thickness of this coating is extremely thin (usually a few microns) and does not continuously cover all structural parts (such as welds, bottom cover edges, etc.). Its main function is chemical protection and cannot block the current path of the entire can body, that is, it does not constitute an insulator in the electrical sense.

The influence of the overall structure of tinplate packaging cans on conductivity

1. Overall metal connectivity

A tinplate packaging can is structurally connected mainly by mechanical folding and resistance welding. The welded part directly passes the current to melt and combine the metal, and the metal continuity is good. This means that even if there is a coating on the surface, the metal inside still maintains a path, ensuring that the current can flow from one end to the other.

2. The influence of coating defects on conductivity

From an electrical point of view, as long as there is a continuous metal path, the current can flow. Even if there is a local insulating coating on the surface, as long as the electrode contact position is not completely isolated, the entire can body can still be regarded as a conductor. In fact, if a tinplate packaging can is placed in a circuit, it can still conduct electricity easily through a metal clip or electrode.

3. The possibility of surface oxidation or corrosion

Under certain conditions, the surface of the tinplate packaging can may form an oxide layer due to the action of air, moisture or chemicals. These oxides (such as iron oxide or tin oxide) have low conductivity, but the oxide layer is too thin to constitute overall insulation and usually does not affect conductivity during use.

Infer the conductivity of tinplate packaging cans from the application perspective

From the perspective of conventional industrial and experimental applications, we can understand that:

·Tinplate packaging cans are regarded as effective conductors in electromagnetic interference (EMI) shielding;

·In electrostatic discharge (ESD) control, metal packaging is classified as a conductive material;

·In fire hazard areas, tinplate packaging cans need to be grounded, which is itself a safety requirement based on their conductivity.

The above phenomenon shows that in actual engineering applications, tinplate packaging cans are consistently identified as conductors.

Experimental verification and electrical measurement basis

If a typical tinplate packaging can is placed in an electrical experiment and the resistance value at both ends is measured with a digital multimeter, it will be found that its resistance is extremely low, usually at the ohm level. This resistance level is much lower than that of semiconductors and insulating materials, reflecting its good conductive properties.

Furthermore, even after multi-layer welding sealing, electroplating, and coating, the resistance value is still far lower than the standard that can be regarded as a "non-conductor" (usually several megohms or higher). This shows that as a whole structure, it fully meets the definition of a conductor in an electrical sense.

Is the tinplate packaging can a conductor or a non-conductor?

Combining the above analysis, we can clearly conclude that:

——Tinplate packaging cans are conductors!

·Tinplate packaging cans are made of metal materials (steel, tin), and their basic materials have typical high electrical conductivity;

·Although there is an organic coating on the surface, the coating does not continuously cover the entire structure, nor does it constitute overall insulation;

·In the actual structure, the metal parts are continuously connected to ensure the integrity of the current path;

·Industrial applications, experimental measurements and physical principles all show that tinplate packaging cans have stable conductive properties.

Therefore, judging from the perspectives of material composition, electrical properties, structural connectivity and engineering practice, tinplate packaging cans are conductors, not non-conductors.

What capabilities does Dekai’s factory offer?

Dekai’s 50,000m² factory in Foshan is a China-based high-quality manufacturer of metal packaging. We operate fully automated production lines: four-color UV tinplate printing, two-color lines, high-speed aerosol and dome can lines, sheet can lines, plus top and bottom lid lines. With production capacity exceeding 300 million printed sheets and 300 million aerosol cans per year, we serve as a comprehensive supplier for wholesale, OEM, and custom manufacturing.