As a metal material, tin sheet has a unique surface property that is closely related to the type of ink used in the printing process. Therefore, whether tin sheet printing service is suitable for beverage packaging must comprehensively consider factors such as the printability of tin sheet, the complexity of the printing process, and consumer demand for beverage packaging.

This article will explore this issue, analyze the application of tin sheet printing service in beverage packaging from multiple perspectives, explore its advantages and disadvantages, and further answer questions of concern to consumers and manufacturers.

Basic principles of tin sheet printing service

What is the process flow of tin sheet printing service?

Tin sheet printing usually uses advanced offset printing technology, flexographic printing technology or screen printing technology. Each printing process has different application methods on the tin sheet surface. The most common are offset printing and flexographic printing.

● Offset printing technology: Offset printing is a traditional printing method that is suitable for mass production, especially with high requirements for color presentation and detail performance. After the tin sheet surface is tin-plated, the surface is very smooth, which makes offset printing have good image clarity and color saturation when printing tin sheet packaging.

● Flexographic printing technology: Flexographic printing is a printing process widely used in the packaging industry, especially suitable for large-scale production. This technology has strong adaptability to printing materials and is suitable for printing on irregular surfaces or metal surfaces. Therefore, it has been widely used in the packaging production of tin sheet beverage cans.

● Screen printing: Although screen printing is usually less used, it also has its unique advantages on some special tin sheet packaging. It can achieve high coverage of ink coating, and the printing effect is relatively strong and durable.

How to ensure the quality of tin sheet printing service?

The quality of tin sheet printing service directly affects the visual effect of packaging and consumers' purchasing decisions. In order to ensure the quality of printing, manufacturers need to take strict control measures, from material selection, selection of printing inks to adjustment of equipment during production. Every step is crucial.

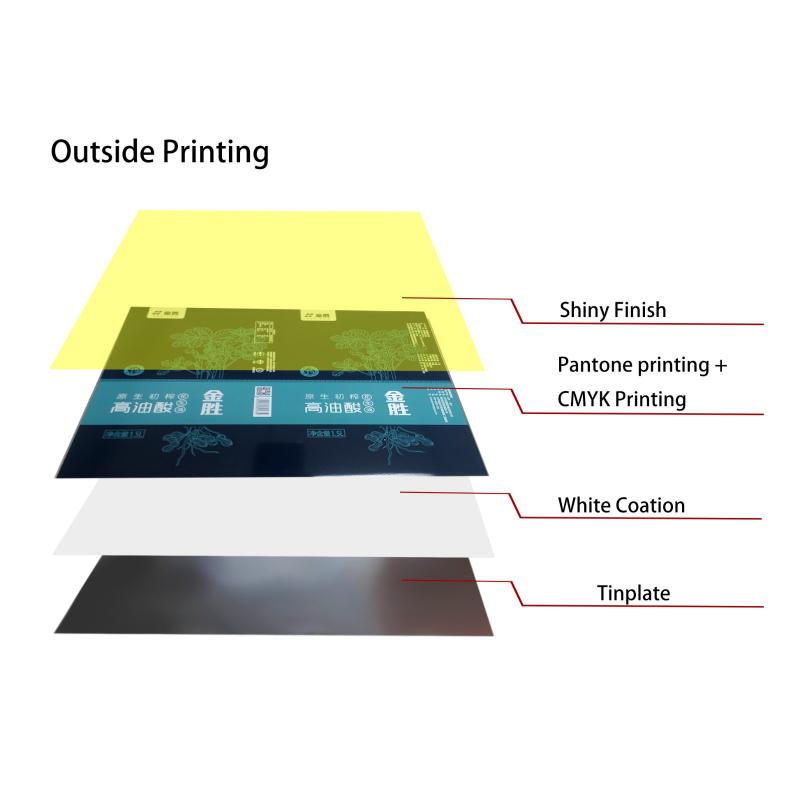

First of all, it is very important to choose ink suitable for metal surface printing. Generally, for tin sheet printing, the ink used needs to have strong adhesion, solvent resistance and wear resistance. Secondly, use advanced printing equipment to accurately control the printing effect to ensure the accuracy of the pattern and the vividness of the color.

Advantages of tin sheet printing service

Why is tin sheet printing suitable for beverage packaging?

As one of the main materials for beverage packaging, tin sheet has many unique advantages. First, tin sheet has good sealing and corrosion resistance, which is essential for protecting the quality of beverages. For beverage products, especially those containing acidic ingredients (such as juice, carbonated beverages, etc.), tin sheet can effectively prevent liquid from contacting the outside world, reduce the possibility of oxidation and other chemical reactions, and ensure the freshness and taste of the beverage.

Secondly, tin sheet packaging has good mechanical strength for beverage products, and can effectively resist external impact during transportation to prevent packaging damage. In addition, tin sheet packaging can withstand ultraviolet radiation and prevent sunlight from causing beverage deterioration.

Can tin sheet printing service improve the aesthetics of beverage packaging?

Another major advantage of printing is that it can show the culture and image of beverage brands to consumers. The surface of tin sheet is very smooth after processing, which is suitable for high-precision pattern and text printing. Through advanced printing technology, manufacturers can print rich colors and fine details on the surface of tin sheet to help beverage products highlight their brand characteristics and enhance market appeal.

The printing effect of beverage packaging plays an important role in the first impression of consumers. A beverage can with exquisite design and vivid patterns can not only attract consumers' attention, but also convey the unique value of the brand. Tin sheet packaging can present a visually impactful packaging effect and enhance brand recognition due to its bright surface and excellent printing adaptability.

How environmentally friendly is tin sheet packaging?

In the current global context of environmental protection and sustainable development, environmental protection has become one of the important criteria for selecting packaging materials. Tin sheet has good recyclability and can effectively reduce resource waste during production and use. Compared with plastic packaging, the recycling rate of tin sheet is much higher, and its reuse value after recycling is higher. Therefore, tin sheet packaging is not only superior in practicality, but also has significant advantages in environmental protection.

Challenges of tin sheet printing service

Is the cost of tin sheet printing service too high?

Although tin sheet packaging has many advantages, the cost of its printing service is often high. Compared with other packaging materials such as plastics and cartons, the production cost of tin sheet printing service is high, especially the investment in coating treatment, ink selection and printing process. This makes it necessary to consider cost factors during the production process of beverage products packaged in tin sheets.

Especially for small and medium-sized beverage manufacturers, higher production costs may become a constraint on the use of tin sheet packaging. In addition, the production cycle of tin sheet printing is also long, and some manufacturers may be subject to certain time constraints.

Can tin sheet printing service meet the needs of large-scale production?

For large-scale beverage companies, production efficiency is a very important consideration. Although tin sheet printing can provide high-quality printing effects, its production efficiency is relatively low. Compared with other packaging forms such as plastic bottles or aluminum cans, tin sheet cans are produced slowly, which may affect the ability to produce in large quantities and deliver quickly.

In addition, the printing of tin sheet packaging requires more complex processes and technologies, which may also lead to quality control problems during the production process. Ink problems, uneven printing or blurred patterns during the printing process will affect the final packaging effect.

The actual situation of using tin sheet printing in beverage packaging

Which beverage brands use tin sheet packaging?

At present, many well-known beverage brands in the world use tin sheet as packaging materials, especially some high-end beverages, functional beverages and canned beer, beverages, etc. For example, some high-end juice and craft beer brands choose tin sheet cans for packaging. With its good sealing and beautiful printing effects, these brands are able to attract consumers through unique packaging.

The printing service of tin sheets has been widely used by these brands. Its colorful and exquisite packaging design gives the brand a higher market value and also makes consumers more interested in and favorable to these beverage products.

What types of beverages are suitable for tin sheet printing service?

The tin sheet printing service is most suitable for packaging beverage products that require high protection performance. For example, juice drinks with high acid ingredients, carbonated beverages with gas, and craft beer, etc., tin sheet cans can effectively prevent liquids from contacting with external factors such as air and sunlight, thereby protecting the quality and freshness of the beverage.

In addition, the high strength of tin sheet packaging is also suitable for beverage products that need to withstand transportation pressure, especially during long-distance transportation and storage. Tin sheet cans can effectively resist external pressure and keep the packaging intact.