Tinplate sheet is a tin-plated steel sheet with excellent corrosion resistance and durability, which is widely used in packaging containers for food, beverages, and chemical products.

As the market's requirements for packaging design are increasing, tinplate sheet, as a hard and smooth material, provides possibilities for various high-quality pattern printing.

The patterns printed on tinplate sheet must not only have bright colors and clear images, but also have high durability to cope with the influence of the external environment.

How to print patterns on tinplate sheet?

Steps for printing patterns on tinplate sheets:

Preparation:

1. Cleaning and degreasing

2. Primer coating

3. Drying treatment

Selection of printing method:

1. Offset printing

2. Screen printing

3. Gravure printing

4. Flexographic printing

Selection of ink:

1. Solvent-based ink

2. UV-curable (UV) ink

3. Water-based ink

Preparation for tinplate printing:

Before printing patterns on tinplate sheets, the surface of the tinplate sheet must be properly treated. This is a key step to ensure that the ink can adhere firmly to the metal surface. Since the surface of the tinplate sheet is smooth and has a protective tin layer, it is difficult to print directly on the untreated surface. Therefore, the printing preparation first needs to deal with the surface adhesion problem.

1. Cleaning and degreasing

During the production process, the tinplate sheet will be exposed to lubricating oil, dust and other impurities. These substances will affect the adhesion of the ink, so the surface of the tinplate sheet must be thoroughly cleaned before printing. Common cleaning methods include using solvents or special cleaning fluids to remove oil stains and ensure that there is no residue on the surface.

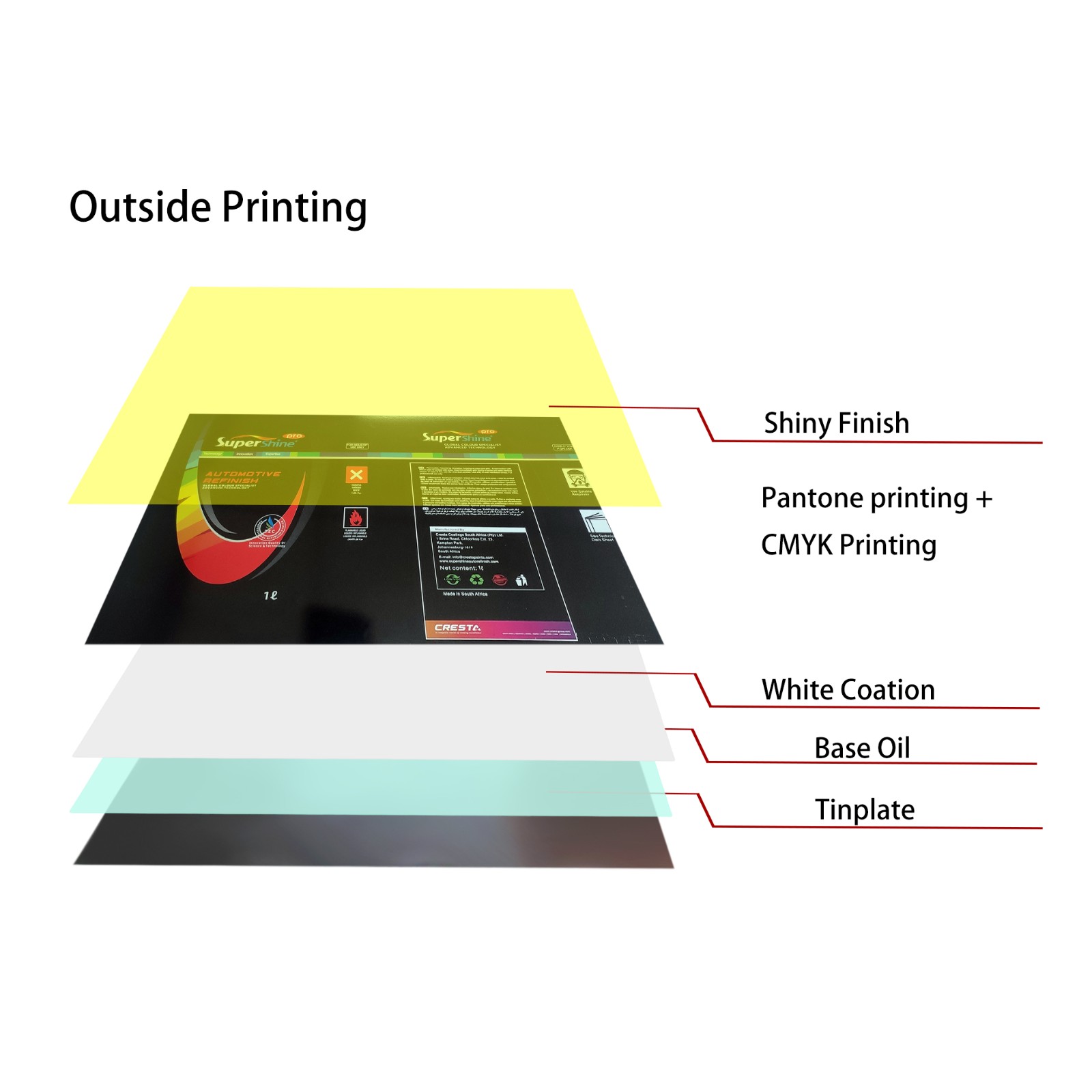

2. Primer coating

In order to further improve the adhesion of the ink, a layer of primer is usually applied to the surface of the cleaned tinplate sheet. The primer can form a relatively rough microscopic surface structure, which enhances the bonding between the ink and the surface of the tinplate sheet. This process plays a vital role in the final printing effect. If the primer is not applied evenly or has quality problems, the ink is prone to fall off or uneven color in subsequent printing.

3. Drying treatment

After the primer is applied, it needs to be dried to ensure that the primer is fully cured and forms a stable surface. This process is usually completed in a drying oven. The drying temperature and time vary depending on the type of primer and the specifications of the tinplate sheet. The purpose of the drying treatment is to provide a solid and suitable foundation for the printing process.

Selection of tinplate printing methods

There are usually several printing methods to choose from for printing patterns on tinplate sheets, mainly including offset printing, screen printing, gravure printing and flexographic printing. Each printing method has its own unique advantages and disadvantages. Choosing the appropriate printing technology depends on the specific printing needs, such as the complexity of the pattern, the printing quality requirements, production efficiency, and cost budget.

1. Offset printing

Offset printing is the most commonly used printing method in tinplate sheet printing. Its principle is to transfer the image to the printing plate by oil-water separation, and then indirectly transfer the image to the tinplate sheet surface through the rubber cloth. Offset printing has extremely high image reproduction accuracy and color expression, and is particularly suitable for processing complex patterns and multi-color printing needs. Offset printing also has high production efficiency and can meet the needs of large-scale production.

2. Screen printing

Screen printing is a technology that directly transfers ink to the substrate through the pores of the screen printing plate. Screen printing is suitable for printing heavy color blocks and single-tone patterns, but performs relatively poorly when processing complex details and gradient effects. Because its resolution is not as high as offset printing, screen printing is more used in some lower-demand pattern printing.

3. Gravure printing

Gravure printing is done by engraving or etching the recessed parts of the image on the metal plate, then filling these grooves with ink and transferring the ink to the surface of the tinplate sheet through high pressure. Gravure printing has extremely high image depth and detail expression, and is suitable for large-area color transitions or large color block printing. Since the platemaking process of gravure printing is complicated and expensive, it is usually used for packaging printing of high-end products.

4. Flexographic printing

Flexographic printing is a printing technology using flexible printing plates, which is suitable for using lower viscosity inks. The image quality of flexographic printing is not as high as offset printing and gravure printing, but its production efficiency is higher and it is suitable for large-scale, low-cost printing needs.

Selection of tinplate printing ink

When printing patterns on tinplate sheets, it is also crucial to choose the right ink. The type and performance of the ink will directly affect the color expression, adhesion, durability and printing effect of the pattern. In tinplate sheet printing, the commonly used inks mainly include the following categories:

1. Solvent-based inks

Solvent-based inks solidify the ink by evaporating solvents. This type of ink is widely used in tinplate sheet printing because of its fast drying speed and strong adhesion. Another major advantage of solvent-based inks is that they are widely adaptable and can be used on a variety of surface conditions. However, solvent-based inks are less environmentally friendly and release volatile organic compounds (VOCs) during the drying process, so environmental protection issues need to be paid attention to when using them.

2. Ultraviolet curing (UV) inks

UV inks are cured instantly by ultraviolet irradiation. Its biggest advantage is that it dries very quickly and does not require volatile solvents. UV inks are suitable for high-precision printing needs, can form a strong adhesion layer on the surface of tinplate sheets, and have excellent wear resistance and corrosion resistance. In food and beverage packaging, UV inks are gradually becoming popular because of their environmental protection and safety.

3. Water-based inks

Water-based inks use water as the main solvent and solidify by water evaporation after drying. They have the advantages of environmental protection and low pollution. Water-based inks have a low viscosity and are suitable for low-pressure printing processes such as flexographic printing. In tinplate sheet printing, water-based inks are relatively rarely used, mainly because their adhesion to metal surfaces is not as strong as solvent-based and UV inks, and they take longer to dry.

What are the key steps in the tinplate printing process?

After completing the surface treatment and ink selection, every step of the printing process is crucial and affects the final pattern quality and stability. The following are several key steps that require special attention in the tinplate sheet printing process:

1. Platemaking

Platemaking is the most basic step in the entire printing process. Whether offset printing, screen printing or gravure printing is used, the production accuracy of the printing plate will directly affect the clarity and accuracy of the pattern. In offset printing, photosensitive platemaking technology is usually used to transfer the image to the printing plate through photosensitive materials. The quality of the printing plate not only determines the edge clarity of the image, but also affects the transition and layering of the color.

2. Ink blending

The blending of inks needs to be carried out strictly according to the formula to ensure color accuracy and consistency. Since there may be slight differences in the surface treatment of different batches of tinplate sheets, the ink ratio and viscosity also need to be adjusted according to the specific situation. At the same time, the ink's viscosity, fluidity, and drying speed properties need to be optimized according to the printing method and equipment to ensure the printing effect.

3. Adjustment of printing equipment

The adjustment of printing equipment is crucial to ensure the quality of the pattern. Parameters such as the pressure, speed, and spacing of the plate cylinder of the equipment need to be precisely adjusted according to the specific printing requirements. Especially in offset printing and gravure printing, excessive pressure may cause the surface of the tinplate sheet to deform, while insufficient pressure will cause unclear image printing. Therefore, the adjustment of printing equipment requires technicians to have rich experience and high sensitivity.

4. Color alignment

In multi-color printing, the accuracy of color alignment determines the clarity and beauty of the final pattern. Each color layer needs to be accurately aligned with the previous color layer to avoid color misalignment or uneven overlap. In the offset printing process, multi-color printing can complete the superposition of multiple colors at one time, so the accuracy requirements of the equipment are very high. The accuracy of color alignment also needs to be guaranteed by regular inspection and calibration of the equipment.

5. Drying and curing

After the tinplate printing is completed, the ink needs to be dried and cured quickly. For solvent-based inks, this process usually relies on natural evaporation or heating drying; for UV inks, instant curing is achieved through ultraviolet irradiation. The speed of drying and curing directly affects production efficiency, and also determines the adhesion and wear resistance of the ink to the surface of the tinplate sheet. In actual operation, the drying temperature and time must be precisely controlled to avoid the flow or deformation of the ink during the drying process.

Tinplate printing: How to carry out quality control and inspection?

After printing is completed, strict quality control and inspection must be carried out to ensure that the printed pattern meets the requirements. Common inspection items include color consistency, pattern clarity, adhesion, wear resistance, etc. Especially in large-scale production, quality inspection is a key step to ensure the consistency of each batch of products.

1. Color consistency

By comparing the color card or the original design drawing, check whether the color of the printed pattern is consistent. If there is a color difference, the parameters of the ink formula or printing equipment need to be readjusted.

2. Pattern clarity

Use tools such as a magnifying glass to check the details of the pattern to ensure that the edges of the printing plate are clear and there is no blur or jaggedness.

3. Adhesion test

The adhesion test usually adopts the scratch or tape test method to check whether the ink is firmly attached to the surface of the tinplate sheet.

4. Abrasion and corrosion resistance

By simulating the wear or corrosion conditions of the external environment, the durability of the printed pattern is tested to ensure that it can maintain good visual effects in actual use.

Can I get cheap and high-quality metal packaging?

Absolutely. Dekai combines large-scale production capacity with China factory efficiency to offer cost-effective packaging. With over 300 million coated/printed items and aerosol cans produced annually, we optimize economies of scale. Our direct sales model—buying from factory to client—ensures low price points without compromising quality.

We provide wholesale discounts, seasonal promotions, and competitive pricing for bulk orders. You’ll get a budget-friendly supplier that delivers durable, high-quality metal cans, end-caps, lids, and licensed printed tinplate for your branding projects.