In our daily lives, we often encounter a variety of canned food and beverage cans, as well as other metal packaging. Among these packaging materials, tin plate cans, as a common form of metal packaging, are widely used for packaging food, beverages, cosmetics, and industrial products due to their excellent properties. Tinplate cans, with their unique advantages such as corrosion resistance, durability, and ease of printing, have become a vital component of the canning industry.

This article will explore the characteristics of tin plate cans in detail and analyze how to identify them through appearance, feel, and user experience, to help consumers better understand this packaging format.

What is a tinplate can?

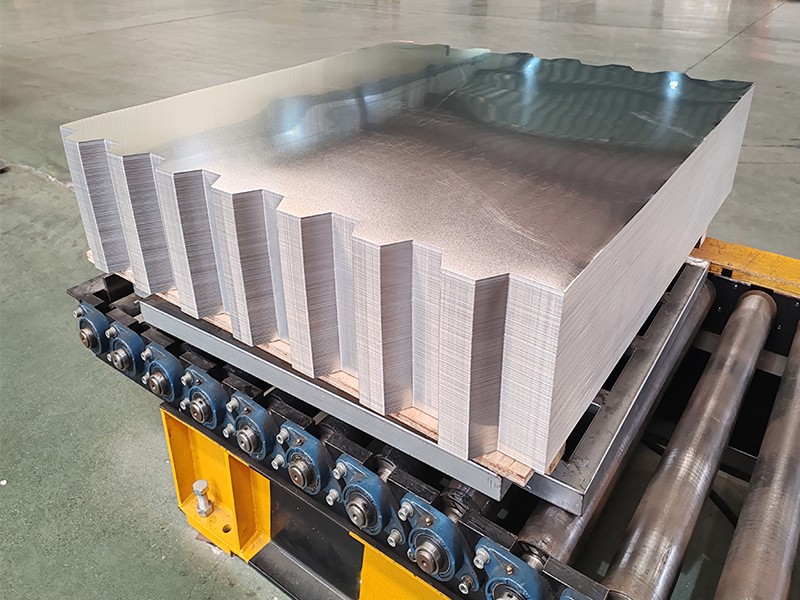

Tinplate is a tin-plated, cold-rolled steel sheet. Tinplate is coated with a layer of tin to enhance its corrosion resistance. This material is widely used in the manufacture of various metal cans, particularly for packaging food, beverages, and other consumer products. As a chemically stable metal, tin forms a protective film on the surface, shielding the steel from direct contact with air, moisture, and other chemicals, thereby slowing down corrosion. Tinplate cans utilize this property, providing excellent protection during daily storage and transportation.

What are the main features of tin plate cans?

Main features of tinplate cans:

1. Excellent corrosion resistance

2. Excellent mechanical strength

3. Good sealing

4. Excellent printability and decorative properties

5. Recyclability and environmental friendliness

Tinplate cans are widely used in the canning industry due to their many significant features. The following will detail the advantages of tinplate cans from various perspectives, including corrosion resistance, strength, recyclability, and printability.

1. Excellent corrosion resistance

One of the most significant features of tin plate cans is their corrosion resistance. By coating the steel surface with a layer of tin, tinplate cans effectively prevent metal oxidation and rust. The tin layer acts as a barrier, preventing direct contact between oxygen in the air and the steel, slowing the onset of oxidation. Furthermore, tin is relatively chemically inert and does not react easily with moisture, acidic or alkaline substances, making tin plate cans highly reliable for long-term storage of food and beverages.

For liquids or acidic or alkaline foods and beverages, corrosion resistance is crucial for ensuring the safety of the contents. Tin plate cans, with their corrosion resistance, effectively protect the food or liquids inside from external factors, thereby extending their shelf life. This is one of the reasons why tin plate cans dominate the food packaging industry.

2. Excellent Mechanical Strength

Tinplate cans offer superior mechanical strength and durability compared to other packaging materials, such as plastic, glass, or aluminum. Cold-rolled steel sheet possesses excellent strength and toughness, capable of withstanding certain external shocks and pressures. This is particularly important for the stability of packaging cans during transportation and storage. For carbonated beverage cans or beer cans, which must withstand internal pressure, the sturdiness of tinplate cans ensures they resist deformation or breakage during transportation.

Furthermore, the sturdiness of tinplate cans makes them safer in daily use, resistant to crushing or puncture. Compared to more fragile glass or easily deformed aluminum cans, tinplate cans offer greater security in applications requiring high strength.

3. Excellent Sealing

During the manufacturing process, tinplate cans are typically sealed using welding or crimping to ensure both airtightness and liquid tightness. High-quality sealing effectively prevents air, moisture, and other contaminants from entering the can, protecting the contents from environmental influences. For canned food or beverages, a good seal is crucial, extending the shelf life while preserving the flavor and quality of the product.

This sealing process ensures the overall quality of the packaging, effectively protecting liquid foods from leakage and gaseous foods from oxidation and deterioration.

4. Excellent Printability and Decorative Properties

Tin plate cans offer excellent printability, which has led to their widespread application. Tinplate's smooth surface and moderate hardness make it easily adaptable to various printing processes, such as offset and UV printing. This printability allows for excellent surface decoration, allowing brands to incorporate intricate designs, logos, and product information, enhancing their appeal.

Furthermore, the surface coating of tin plate cans can be customized to enhance durability, aesthetics, or functionality. This coating not only protects the tin layer and steel plate from further corrosion but also provides additional resistance to wear and scratches.

5. Recyclability and Environmental Protection

Tinplate cans are a highly effective and environmentally friendly packaging material in the canning industry. Because they are primarily composed of steel, they have an extremely high recyclability rate. Used tinplate cans can be recycled and reused back into the production process without losing their essential physical and chemical properties. Compared to other packaging materials such as plastic, tinplate cans have a relatively low recycling cost and enable efficient material recycling.

This characteristic gives tinplate cans a significant advantage in the modern, environmentally conscious packaging market, and more and more brands are choosing tinplate packaging to reduce their carbon footprint and environmental impact.

How to Identify Tin plate Cans?

After understanding the characteristics of tin plate cans, consumers can now identify them in their daily lives. Here are a few simple ways to identify tin plate cans:

1. Appearance

Tin plate cans typically have a smooth surface with a metallic sheen. This is because the tin coating itself creates a silvery-white reflective effect, while the coating and printing also contribute to the can's glossy appearance. Tinplate cans often feature intricate designs and printed text, which are more detailed and clear than those found on ordinary metal cans.

In addition, the edges and seams of tin plate cans are often crimped or welded, resulting in a smooth appearance without noticeable burrs or roughness.

2. Touch

Touch cans can also help identify tin plate cans. Due to the tin coating, tin plate cans typically feel smoother and more delicate than steel cans. While all metal cans have a certain degree of hardness, tin plate cans, due to the properties of steel, feel heavier and harder than aluminum cans.

Gently tapping the can will produce a crisp, metallic sound, while aluminum cans have a duller, more resonant sound. This is also an effective way to quickly identify the material of a metal can.

3. User Experience

Consumers can further distinguish tin plate cans through user experience. For example, tin plate cans generally offer a good seal when opened, accompanied by a slight "hissing" sound. This is due to the interaction between the air pressure inside the can and the outside air. Aluminum cans, on the other hand, are relatively poor at sealing when opened.

Furthermore, tinplate cans are often used to hold highly acidic or highly carbonated beverages without significant deformation or damage, which is an advantage over aluminum cans.

Comparison of Tinplate Cans with Other Metal Cans: Which is Best?

To more clearly distinguish tinplate cans, we can compare them with other common metal cans, such as aluminum cans:

1. Tinplate Cans vs. Aluminum Cans

• Corrosion Resistance: Tinplate cans, due to their tin coating, offer superior corrosion resistance compared to aluminum cans. Tinplate cans offer extended protection, especially when packaging acidic foods or beverages.

• Strength: Tinplate cans have high mechanical strength and are less prone to deformation, while aluminum cans are lighter, weaker, and more susceptible to deformation due to external forces.

• Sealability: Tinplate cans generally offer better seals and are particularly suitable for products that are subject to high pressure or require long-term storage.

2. Tinplate Cans vs. Glass Cans

• Portability: Tinplate cans are lighter and more resistant to breakage than glass cans, making them suitable for transport and portability, while glass cans are more susceptible to breakage during handling.

• Cost: In terms of production and recycling costs, tin plate cans are cheaper than glass cans and are more convenient and efficient to recycle.

What makes Dekai tinplate packaging stand out in China?

Foshan Dekai Metal Packaging Co., Ltd. is a professional metal packaging manufacturer and supplier in China, operating from a 50,000㎡ factory. With advanced production lines such as FUJI UV four-color tinplate printing machines and high-speed aerosol can assembly, we guarantee high-quality and low-price tinplate products. Customers can buy wholesale tinplate cans, customized lids, and aerosol packaging directly from our factory.