In the modern packaging industry, tinplate cans are widely used in many fields such as food, cosmetics, and chemical products due to their excellent corrosion resistance, durability, and recyclability. Compared with other materials, tinplate cans can not only effectively protect product quality, but also bring higher market value and brand recognition to products.

However, how to choose the tinplate can packaging suitable for your products often poses challenges to many companies. Correctly selecting the type and specification of tinplate can packaging can not only improve the market competitiveness of products, but also reduce production costs and extend the shelf life of products. This article will analyze in detail from multiple perspectives how to choose the tinplate can packaging suitable for your products.

What factors should be considered first when choosing tinplate can packaging?

How does the nature of the product affect the choice of packaging?

When choosing a suitable tinplate can packaging, the first factor to consider is the nature of the product. Different types of products have different requirements for packaging. Taking food as an example, the main goal of food packaging is to keep food fresh, avoid external contamination, and extend the shelf life. For foods with high water content or strong acidity (such as canned fruit, yogurt, etc.), tinplate cans should have strong corrosion resistance and need an inner coating to prevent chemical reactions between food and metal, affecting taste or safety. For foods such as dry goods and condiments, more attention may be paid to sealing and moisture resistance.

For non-food products, such as cosmetics, medicines, chemical raw materials, etc., the function of their packaging is not only to protect the contents, but also to attract consumers in terms of appearance design. Therefore, the tinplate can packaging of such products may pay more attention to surface decoration, such as printing effects, label design, etc.

What is the impact of the size and shape of tinplate cans on the packaging effect?

When choosing tinplate cans, the size and shape of the product is another important factor that must be considered. The size and shape of tinplate cans will directly affect the storage, transportation and display effects of the packaging. Larger cans are suitable for products with larger storage volumes, such as large food cans, seasoning cans, etc., while smaller cans are more suitable for packaging small cosmetics, perfumes, candies, etc. Cans of different shapes also have different functional requirements. Traditional round tinplate cans are usually used for most food packaging, but special shapes such as square, oval or special-shaped cans are more common in cosmetics or gift packaging, which can better convey the high-end and uniqueness of the product.

In addition, the design of the can body should take into account the convenience of consumers when using it. For example, some tinplate cans with inner lids or easy-tear lids are more suitable for quick opening and reuse, which is suitable for fast-moving consumer products, while products that need long-term storage may pay more attention to sealing and moisture resistance.

Why are the materials and coatings of tinplate can packaging important?

Why do tinplate cans need inner coatings?

The inner coating of tinplate cans is also a very critical factor when choosing packaging. Tinplate cans usually need to be tinned and coated with an anti-corrosion coating on the inside. The main function of this coating is to prevent the contents of the can from contacting the metal, avoiding chemical reactions and affecting the quality and safety of the product. In particular, for acidic, oily or high-water foods, the inner coating plays a vital role.

For food products, the inner coating must meet relevant food safety standards to ensure that no harmful substances are released into the product. For example, some low-quality inner coatings may release harmful substances due to high temperature or other changes in external conditions, causing food contamination. Therefore, when choosing tinplate can packaging, be sure to confirm whether the inner coating meets the relevant food safety standards, especially for high-end food brands. This link is particularly important.

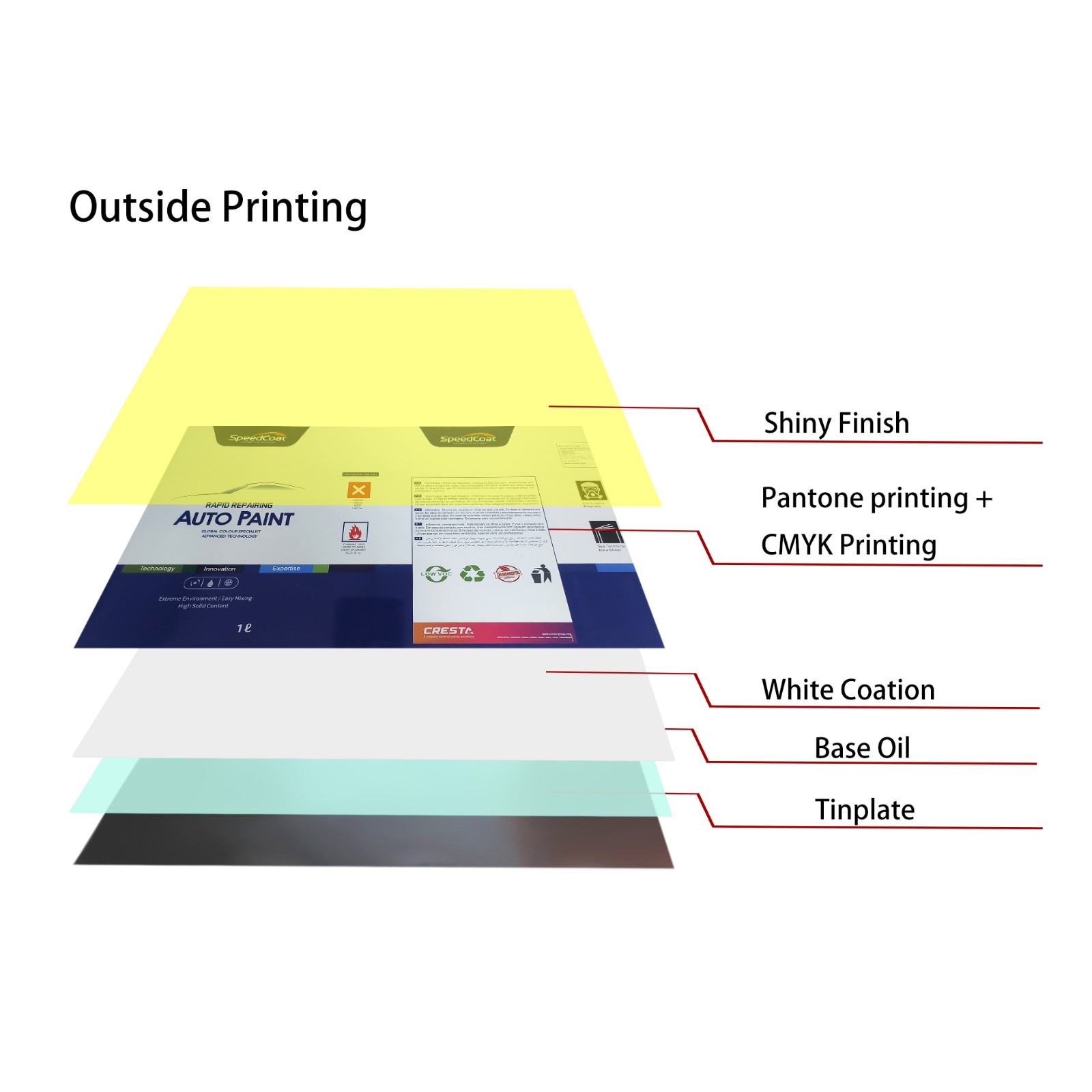

What are the effects of the outer coating on tinplate cans?

In addition to the inner coating, the outer coating of tinplate cans is also very important, which directly affects the appearance and printing effect of the can. The outer coating mainly plays the role of protecting the appearance, improving the aesthetics and preventing corrosion. When printing, the quality of the coating determines the adhesion and durability of the ink, thereby affecting the clarity and durability of the final printing effect. High-quality coatings can not only effectively resist external damage such as friction and scratches, but also prevent rust on the surface of the can during the packaging process.

Therefore, for products that need to display exquisite design and high-quality brand image (such as cosmetics, alcohol, etc.), it is crucial to choose a suitable outer coating. For general daily consumer goods, the main function of the outer coating is to enhance durability and extend the service life of the can.

How to ensure the safety of tinplate can packaging?

Are tinplate cans suitable for all types of products?

Not all types of products are suitable for tinplate can packaging. When choosing tinplate cans, the chemical stability of the product must also be considered. Certain strong acids or alkaline substances may corrode the coating of tinplate cans, causing the can to fail. For example, some specific chemicals may react with metals to produce harmful gases or contaminate the contents. Therefore, when choosing packaging materials, it is necessary to clearly understand the composition and stability of the product to ensure that the use of tinplate cans can remain safe for a long time.

Especially for products containing corrosive ingredients, tinplate packaging should be avoided, or the inner coating of the can needs to be specially treated to increase corrosion resistance.

How to test the sealing and pressure resistance of tinplate can packaging?

The sealing and pressure resistance of tinplate cans directly affect the quality and shelf life of the product. Especially for food products, the sealing of the packaging is crucial, and any tiny air entry may cause oxidation or deterioration of the food. Therefore, when choosing tinplate can packaging, its sealing performance must be tested.

In addition, the pressure resistance of the can is also an important criterion for measuring the quality of tinplate can packaging. Especially during transportation, external pressure may affect the structure of the can, causing leakage of contents or quality damage. Conducting pressure resistance tests can ensure that the packaging can effectively resist various external forces during transportation and stacking, and ensure the safety of the product throughout the supply chain.

How to choose the right tinplate can packaging according to brand positioning?

How should high-end brands choose tinplate can packaging?

For high-end brands, packaging is not only a tool for product protection, but also a reflection of brand image. High-end food, cosmetics, beverages, etc. usually need to choose tinplate can packaging with unique design and high quality. This type of packaging requires not only exquisite craftsmanship and high-quality materials, but also ensures that it is highly consistent with brand positioning. In addition to paying attention to materials and coatings, appearance design, printing effects, brand logos, etc. are also important considerations when choosing tinplate cans.

For example, tinplate cans with a metallic texture or special shape can make the product stand out on the shelf and increase consumers' desire to buy. At the same time, exquisite appearance design can establish a high-end and professional brand image in the minds of consumers, thereby enhancing the brand's market awareness.

How should ordinary brands balance cost and quality?

For most brands, how to balance cost and quality is the core issue when choosing tinplate can packaging. Although high-quality packaging materials and printing processes can help improve the market competitiveness of products, excessive packaging costs may lead to increased pricing pressure on products. At this time, companies need to choose appropriate packaging materials based on their budget and product positioning. On the basis of ensuring the packaging protection function and quality, try to choose tinplate cans materials and printing processes with high cost performance to achieve the best cost-effectiveness.