As a common metal material, tinplate (tin-coated steel) is widely used in various packaging containers, especially in the food and beverage industry, where it is widely adopted for its excellent corrosion resistance, strength and processing performance. However, when used in outdoor environments, the durability of tinplate packaging cans has become an important issue that needs to be explored in depth. In particular, the variable climate conditions in outdoor environments (such as high temperature, humidity, acid rain, strong wind, etc.) may have a certain impact on the performance of packaging cans, affecting their protective functions and long-term use effects.

This news will deeply analyze the durability of tinplate packaging cans in outdoor environments, explore its advantages and disadvantages, reveal some factors that affect its durability, and analyze how to improve its service life in harsh environments by improving design and processing technology.

Why do tinplate packaging cans need special durability in outdoor environments?

What are the basic characteristics of tinplate?

Tinplate is a metal material with a low-carbon steel base material and a thin tin layer on the surface. The tin layer not only provides corrosion resistance, but also improves the gloss and processing properties of the metal. Therefore, tinplate packaging cans have become one of the most widely used packaging materials because of its lightness, strength and good sealing performance. Especially in outdoor environments, tinplate can effectively resist the damage of external substances to the contents, such as moisture, air and microorganisms.

However, the durability of tinplate is not perfect, especially when exposed to outdoor environments for a long time. Moisture, ultraviolet rays, temperature fluctuations and chemicals may have adverse effects on its appearance and inner layer, so when used in outdoor environments, the effects of these external factors must be considered.

What are the effects of outdoor environment on tinplate?

The variability of outdoor environment is one of the key factors affecting the durability of tinplate packaging cans. The following environmental conditions have a direct impact on the durability of tinplate:

● Humidity and moisture: Moisture is one of the main causes of metal corrosion. Tinplate is susceptible to corrosion in a humid environment, especially in high humidity, oxygen and moisture react with the metal surface, thereby accelerating the oxidation process and causing rust.

● Temperature changes: Sharp changes in outdoor temperature (such as high temperatures in summer and low temperatures in winter) may also affect the structure and performance of tinplate packaging cans. High temperatures can cause internal pressure to increase, while low temperatures can make the can brittle, affecting its sealing and durability.

● Ultraviolet radiation: The coating of tinplate packaging cans will gradually degrade after long-term exposure to ultraviolet rays. Ultraviolet rays not only damage the appearance of the can, but may also cause the coating to lose its anti-corrosion effect.

● Wind and sand and particles: In some areas with frequent sandstorms or strong winds, the surface of tinplate packaging cans may be damaged by friction and erosion by sand particles. Wind and sand particles may scratch off the coating, exposing the metal substrate, which in turn causes corrosion.

Advantages and challenges of tinplate packaging cans for outdoor use

What are the advantages of tinplate packaging cans?

● High strength and durability: Tinplate has high mechanical strength, which enables it to withstand certain external pressure and impact, which is particularly important for packaging requirements in outdoor use environments. For example, during transportation, tinplate cans can effectively protect the contents of the can from damage.

● Good sealing: Tinplate packaging cans have very good sealing, which can effectively prevent air and moisture from entering the can, thereby ensuring the long-term preservation of the contents, especially in food and beverage packaging, to maintain the freshness and quality of the contents.

● Recyclability and environmental protection: Tinplate materials have strong recycling value and can be processed into new packaging cans after use, which meets the requirements of modern environmental protection, especially in outdoor activities, the environmental protection of packaging waste is increasingly valued.

● Corrosion resistance: Although tinplate itself is susceptible to moisture and oxidation, the tin layer and coating on its surface can effectively provide a certain degree of corrosion resistance. This makes tinplate packaging cans resistant to outdoor moisture erosion under certain conditions.

Challenges: Disadvantages in outdoor use

However, despite the many advantages of tinplate, its durability in outdoor environments also faces many challenges:

● Long-term exposure may lead to rust: As mentioned earlier, moisture and oxidation are the biggest threats to the durability of tinplate packaging cans. Even if the coating can provide temporary protection, long-term exposure to outdoor humid environments may cause damage to the tin layer and coating, causing the metal to rust and affect the integrity of the can.

● Risk of coating damage: Even if tinplate has strong corrosion resistance, the coating may still peel or wear due to external forces, friction and other factors. When the coating is damaged, the metal substrate is exposed to the external environment and is easily corroded.

● UV damage: UV radiation may cause the coating to degrade and affect its anti-corrosion effect. Especially in an environment exposed to direct sunlight for a long time, the appearance of tinplate packaging cans will fade, wrinkle or even crack, thus affecting its aesthetics.

● Alternating effects of high and low temperatures: drastic changes in temperature may have a negative impact on the sealing and structural stability of tinplate. High temperature may cause the pressure inside the can to increase, while low temperature may make the can brittle, causing cracking or deformation.

How to improve the durability of tinplate packaging cans in outdoor environments?

Strengthening coating and anti-corrosion treatment

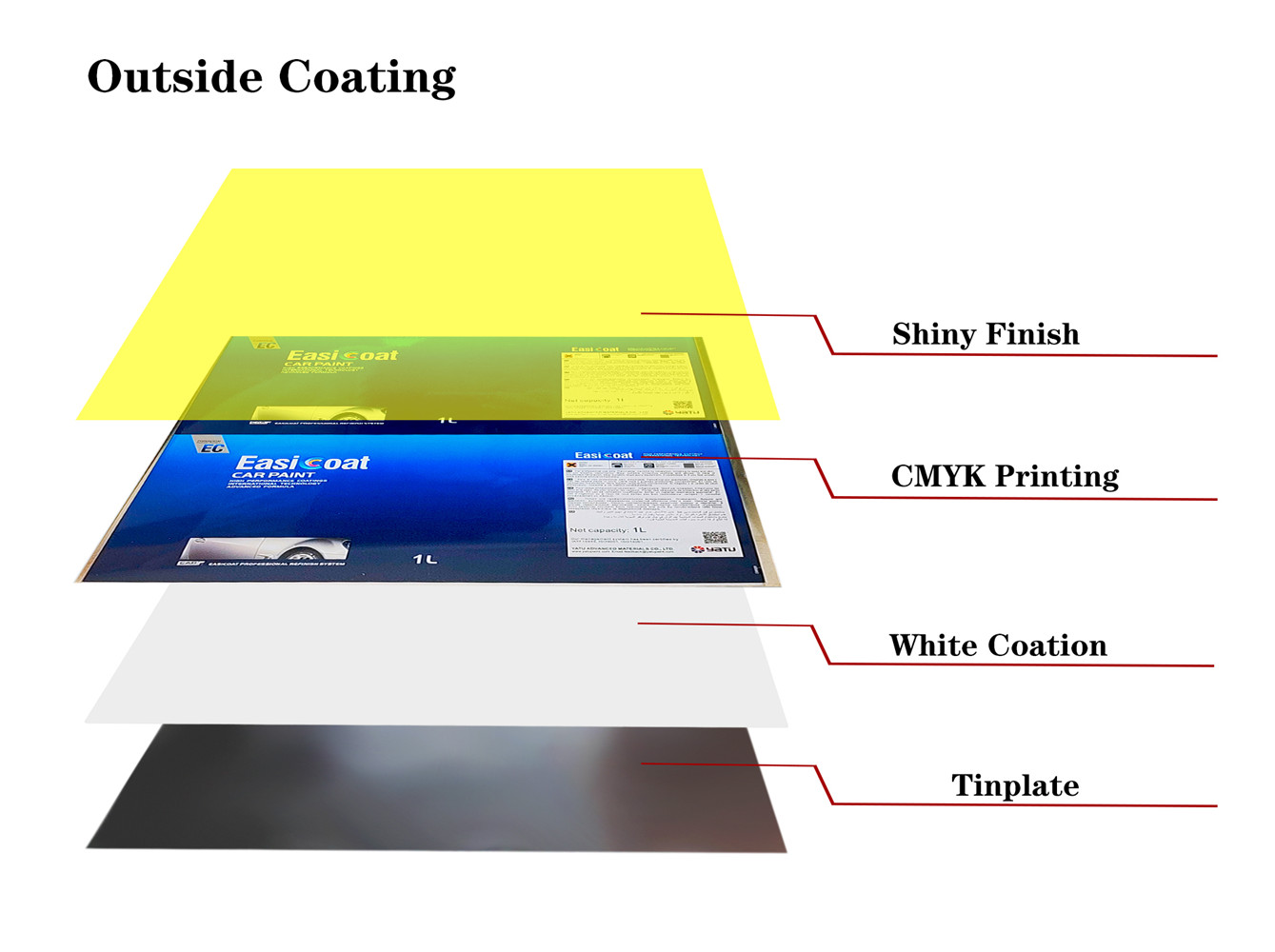

In order to improve the durability of tinplate packaging cans in outdoor environments, strengthening the anti-corrosion coating is a crucial step. By applying a more durable anti-corrosion layer to the tinplate surface, such as epoxy resin coating or polyurethane coating, its resistance to moisture, oxidation and UV radiation can be enhanced.

In addition, the thickness and uniformity of the coating are also very important during the production process. A uniform and thick coating can provide more lasting protection and effectively prevent moisture penetration and chemical reactions.

Choose the right environmental packaging design

In addition to the coating, the design of tinplate packaging cans is also an important factor in improving durability. The design should take into account the special needs of outdoor environments, such as anti-slip design, pressure-resistant structure and UV protection design. For example, adding reinforcement design to the top and bottom of tinplate packaging cans can enhance its pressure resistance and avoid deformation caused by external pressure.

Pay attention to storage and transportation conditions

Even tinplate packaging cans that have been treated with rust prevention and special designs are still affected by storage and transportation conditions. Therefore, during storage and transportation, avoiding exposure to moisture, extreme temperatures or strong UV radiation can significantly extend the service life of the packaging cans.

Regular inspection and maintenance

In order to ensure the good performance of tinplate packaging cans in outdoor environments, regular inspection and maintenance are also measures that cannot be ignored. After long-term outdoor use, the can body should be checked for damage, signs of corrosion, and the integrity of the coating so that the damaged packaging can be repaired or replaced in time.