Tinplate sheet, a high-quality metal material, is widely used in a variety of food, beverage, and cosmetic packaging. Not only does it offer excellent corrosion and moisture resistance, but its smooth surface and superior printability make it the preferred material for many brands to showcase their product images.

Offset printing plays a key role in the tinplate printing process, giving these metal packaging a refined appearance. As demand for refined and visually appealing product packaging increases, offset printing in tinplate printing has become a hot topic of discussion.

So, does offset printing use ink in tinplate printing? The answer is yes, but the details behind this are far more complex than a "yes or no" answer.

This article will delve into the basic principles of offset printing and explore the use of ink in tinplate printing, including ink types, properties, application steps, and the important role it plays in tinplate sheet packaging.

Tinplate Sheet: How Does Offset Printing Work?

Offset printing is a common printing technique widely used for printing on various substrates, including paper, metal, and plastic. Its core principle is based on the principle that oil and water do not mix. The ink is transferred from the printing plate to a blanket cylinder, which then transfers the image to the substrate.

During the offset printing process, the printing plate contains both an image and a blank area. The image is oleophilic and hydrophobic, while the blank area is hydrophilic and repellent. Fountain solution (water) first covers the blank area of the plate to prevent ink from adhering, while ink is applied to the image area to form the printed pattern. The ink pattern is then transferred by a roller and precisely applied to the metal surface.

In the tinplate sheet printing process, offset printing offers the advantages of high printing precision, vibrant colors, and excellent stability, enabling the production of complex patterns and multi-color printing on metal surfaces. The use of ink is a core part of the entire process, determining the color quality, durability, and visual impact of the final print.

What types of inks are used in tinplate sheet offset printing?

Tinplate sheet offset printing relies on inks, which differ significantly from those used in other types of printing, such as screen printing and gravure. Due to the unique demands of tinplate sheet offset printing, inks must not only ensure precise transfer, but also exhibit strong adhesion to metal surfaces and abrasion resistance.

The following describes two common types of inks:

1. Solvent-based Inks

Solvent-based inks are the most common type of ink used in traditional offset printing. They are based on organic solvents. The solvent in the ink facilitates flow and allows it to flow smoothly between the roller and the printing plate during printing, effectively transferring the image. The greatest advantage of solvent-based inks is their fast drying speed and low cost, making them suitable for high-volume production.

In tinplate printing, solvent-based inks can be cured by heat drying or natural drying. Once the ink is applied to the tinplate sheet, the solvent evaporates rapidly, leaving behind the pigment and resin, forming a stable coating. Once dried, these inks exhibit excellent abrasion resistance and water resistance, providing long-term protection for tinplate sheet packaging.

However, solvent-based inks also have certain disadvantages, particularly in terms of environmental protection. The organic solvents in the ink evaporate during the drying process, producing volatile organic compounds (VOCs), which can have certain impacts on the environment and the health of operators. Therefore, with increasing environmental protection requirements, many manufacturers are seeking alternatives.

2. UV Curing Inks

UV curing inks are an environmentally friendly ink that has become increasingly popular in tinplate printing in recent years. Unlike solvent-based inks, UV inks dry not through solvent evaporation but through ultraviolet light, rapidly curing. UV inks contain photosensitive polymers that, when exposed to ultraviolet light, polymerize, transforming from a liquid to a solid state, creating a wear-resistant pattern.

UV curing inks offer several significant advantages:

• Fast drying: UV inks cure almost instantly, significantly improving production efficiency.

• Environmentally friendly: Because UV inks contain no organic solvents, virtually no harmful gases are emitted during the curing process, meeting the environmental protection requirements of modern industry. • High Adhesion and Gloss: UV inks form a stronger, more glossy coating after curing, creating a more refined visual effect for tinplate printing.

Although UV inks are relatively expensive, with increasingly stringent environmental regulations and technological advancements, they are gradually replacing traditional solvent-based inks and becoming the mainstream choice for tinplate sheet offset printing.

What are the steps for applying inks in tinplate sheet offset printing?

On a tinplate sheet offset printing line, the ink application process is relatively complex and highly precise. The entire process requires careful control of ink thickness, color blending, and drying to ensure the desired print results.

1. Ink Preparation and Mixing

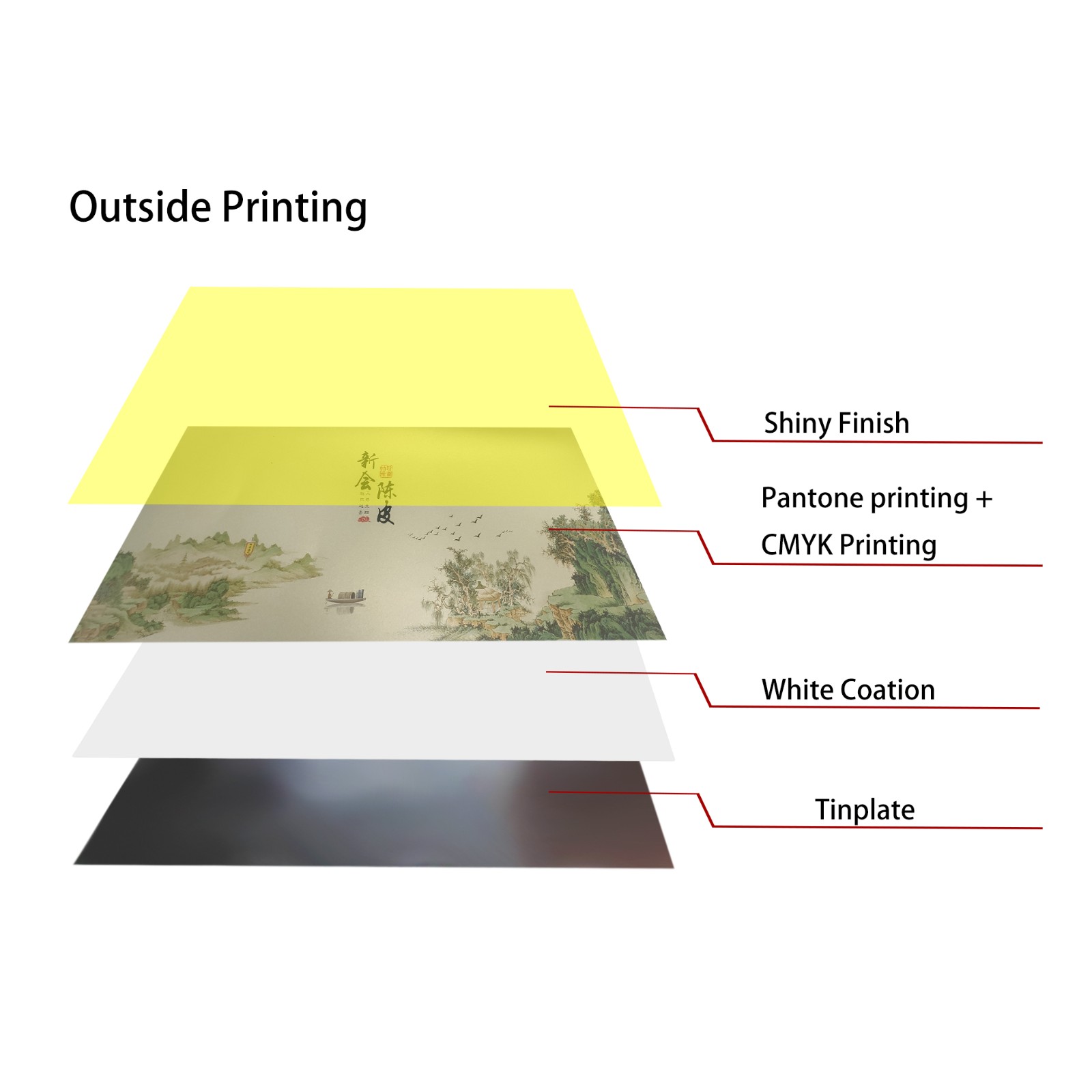

Before printing, technicians prepare the inks according to the design. The ink colors must be carefully mixed to ensure that the final print color matches the original design. Ink color matching is particularly important for multi-color printing. Typically, offset printing uses the four colors CMYK: cyan, magenta, yellow, and key/black. The superposition of these four basic colors creates a rich color expression.

2. Ink Transfer and Application

In offset printing, ink is precisely applied to the substrate (i.e., the tinplate sheet) through the image area on the printing plate. This process is accomplished through repeated pressure from the cylinder and rubber blanket. Adjusting the printing pressure and speed is crucial to ensuring even ink distribution and a clear image.

3. Ink Drying and Curing

Depending on the ink type, the drying method varies. For solvent-based inks, drying typically occurs through heat or natural ventilation, allowing the solvent to evaporate and dry. UV inks, on the other hand, cure rapidly through ultraviolet light. The drying process is critical; excessively fast or slow drying can affect print quality. Ink that does not dry thoroughly may blur the image or cause scratches and damage in subsequent packaging.

4. Surface Treatment and Finishing

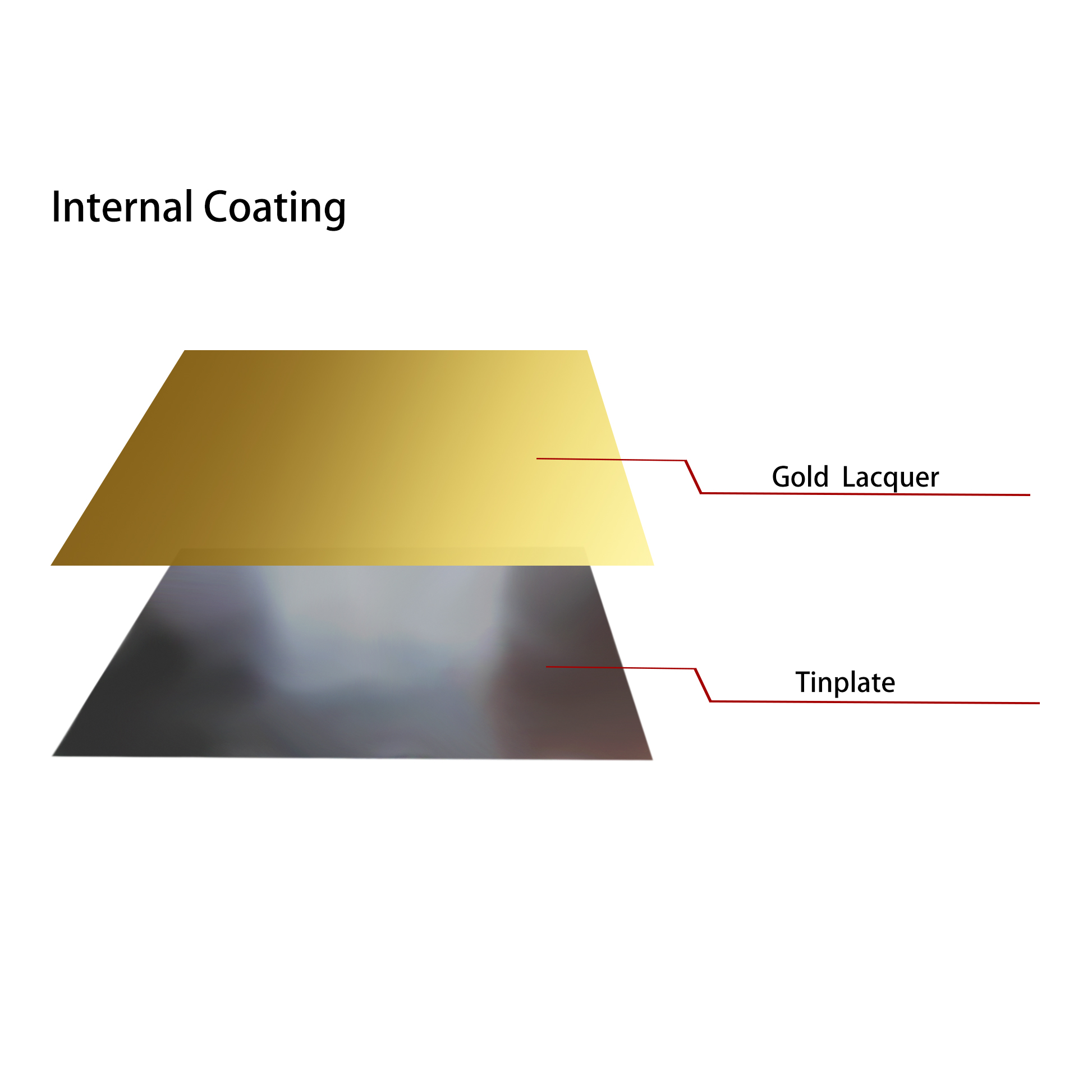

After the ink has dried or cured, the tinplate sheet may undergo further surface treatment to enhance the wear resistance and aesthetics of the packaging. Common surface treatments include lamination, varnishing, or painting. These treatments not only enhance the brightness of printed materials but also effectively protect the ink patterns, preventing them from fading or damage due to environmental influences.

What is the role of ink in tinplate sheet offset printing?

Ink in tinplate sheet offset printing goes beyond simply applying color; it directly impacts the visual quality of the entire package, the product's appeal, and its longevity. Here are several key roles ink plays in tinplate printing:

1. Imparting a Stunning Appearance

Ink is the most intuitive way to present tinplate sheet packaging. Through offset printing, designers' creativity can be perfectly expressed on the tinplate sheet surface. From food packaging to cosmetics boxes, the colors, patterns, and text on every product packaging rely heavily on precise ink rendering.

2. Improving Package Recognition and Market Competitiveness

In the modern market, packaging design is directly linked to product sales performance. Through high-quality offset printing technology and a rich selection of ink colors, companies can give their products a unique brand image, helping consumers quickly identify them among numerous products.

3. Protecting Product Contents

While tinplate sheet itself offers strong corrosion and moisture resistance, the use of ink can provide further protection. A specially treated ink coating increases the wear and oxidation resistance of metal packaging, extending the shelf life of your product.

Where is Dekai located and what are the benefits of working with a China-based supplier?

Dekai is based in Foshan, Guangdong province, a major industrial hub in southern China. Our strategic location, large-scale factory, and automated production give us a significant advantage in offering low-priced metal packaging without compromising on quality.

By sourcing directly from our factory, global buyers benefit from discounts, customization options, and efficient shipping logistics.