As the demand for environmentally friendly and efficient products in the industrial field continues to increase, many traditional chemical cleaning products are gradually replaced by efficient and more environmentally friendly alternatives. Fuel system cleaners, as one of the important products in the automotive maintenance industry, are experiencing rapid market expansion. To ensure that fuel system cleaners can effectively remove carbon deposits, sludge and other pollutants inside the engine, the design and performance of the spray bottle are particularly important.

Today, we will take a deep look at a new product - 300ml empty metal spray cans, which plays a vital role in the spraying process of fuel system cleaners.

1. Design and features of 300ml empty metal spray cans

300ml empty metal spray cans are a packaging solution tailored for fuel system cleaners, a high-demand chemical product. The spray bottle is made of high-quality tinplate material, which has excellent corrosion resistance and high strength, enabling it to maintain stability in an environment with long-term contact with chemicals. Tinplate is a metal material with a tin layer on the surface of an iron plate. Its superior anti-corrosion properties make it the preferred material in the field of chemical packaging.

The spray bottle has a capacity of 300ml, which is suitable for the fuel system cleaning needs of various vehicles. Its design is ergonomic, and users can easily master and operate it efficiently. The size and shape of the bottle are carefully designed to ensure that each spray can evenly and accurately spray the detergent to all parts of the engine fuel system, avoiding waste and ensuring the maximum effectiveness of the detergent.

2. Product performance and technical parameters

The 300ml empty metal spray can not only has excellent physical properties, but also has excellent spray performance, which meets the strict requirements of chemical industry products for packaging materials and design. The following are the main technical parameters of the product:

Seal type: pump sprayer

This product adopts the pump sprayer sealing method, which has an efficient and uniform spray effect. The pump spray design can ensure the stability of the spray pressure and spray volume of the detergent, avoid excessive spraying or uneven spraying, and thus improve the use efficiency of the fuel system cleaner.

Surface treatment: gloss

The surface of the spray bottle is glossy, which not only has an elegant appearance, but also can resist scratches, stains and other marks that may appear after long-term use, and maintain a clean and bright appearance.

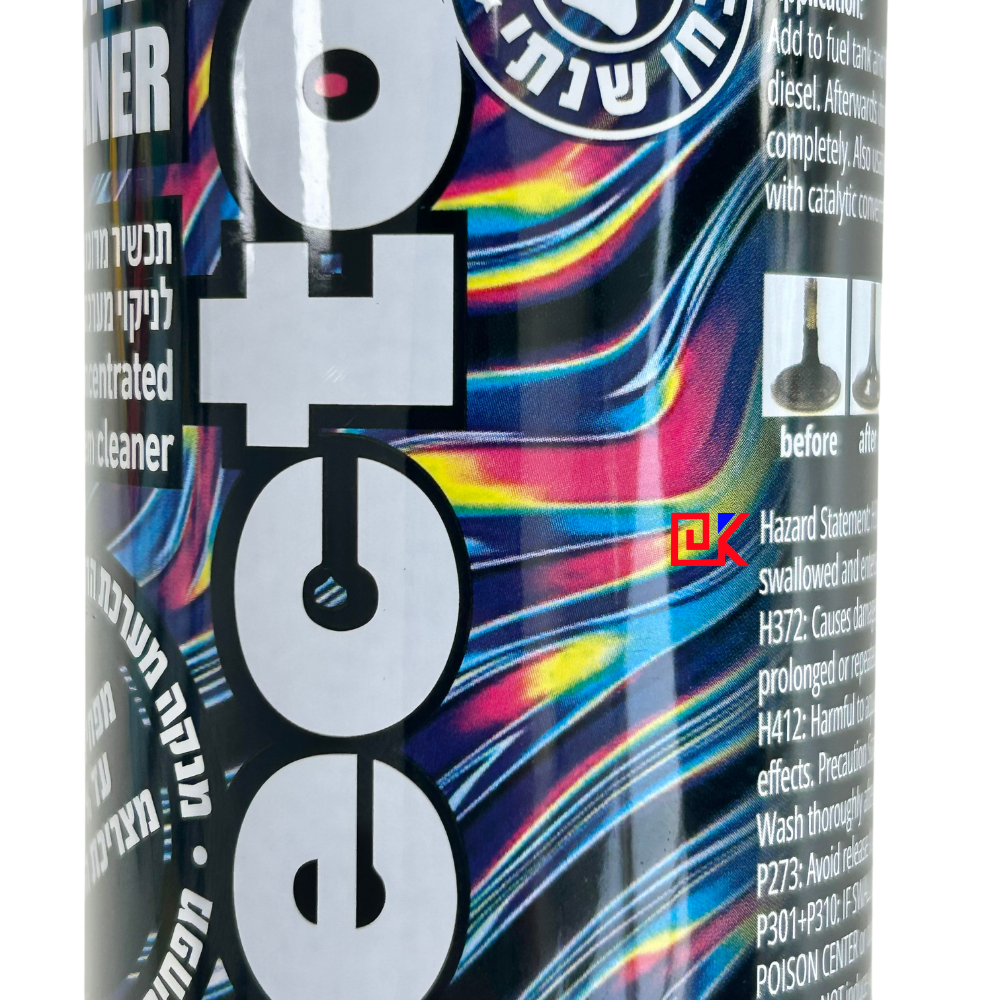

Printing process: CMYK offset printing

Use CMYK offset printing technology for high-quality printing, ensuring that the logo and pattern of each spray bottle can be clearly presented. Users can print their own brand LOGO on the bottle according to their needs to further enhance the brand's market exposure.

Diameter and height

The diameter of the spray bottle ranges from 45 to 70 mm, suitable for various sizes of fuel system cleaner containers. The height can be adjusted between 100 mm and 240 mm according to different design requirements to ensure that the bottle can adapt to different spray needs.

Spray pressure and deformation pressure

This spray bottle has extremely high pressure resistance, and its spray pressure is as high as 1.4Mpa, ensuring that the cleaner can be effectively sprayed to every corner of the fuel system under high pressure conditions. At the same time, the deformation pressure requirement of the bottle is ≥1.2Mpa, which can withstand external pressure and maintain a stable spray effect.

Environmental protection and certification

The 300ml empty metal spray can has passed the ISO9001 quality management system certification, ensuring that it is produced in strict accordance with international quality standards during the manufacturing process. At the same time, the materials and production processes used meet environmental protection requirements and avoid environmental pollution.

3. Market demand and development trend of fuel system cleaners

The cleaning of the fuel system is a key link in automobile maintenance. With the continuous development of automobile technology and the increasing requirements of consumers for automobile performance, the market demand for fuel system cleaners is also growing steadily. Especially for modern automobile engines, the fuel system is prone to accumulate carbon scale, sludge and other sediments after long-term use. These sediments not only affect the combustion efficiency of the fuel, but also may cause the engine power to drop and the fuel consumption to increase. In severe cases, it even affects the normal operation of the engine. Therefore, the use of fuel system cleaners has become an important means to improve automobile performance and extend engine life.

4. Advantages of empty metal spray cans

As an important packaging form of fuel system cleaners, the advantages of empty metal spray cans are not only reflected in the superiority of their materials, but also in their direct impact on the use effect of the product.

Anti-corrosion and high pressure resistance

The empty metal spray can is made of tinplate and has excellent anti-corrosion ability. When in contact with chemicals such as fuel system cleaners, it can effectively prevent corrosion and deformation of the bottle body and ensure the long-term storage and stability of the cleaner. In addition, the spray bottle has high pressure resistance and can withstand greater pressure, ensuring uniform and continuous spraying effect.

Spray uniformity and efficiency

The pump sprayer seal design ensures the stability of the spray pressure, enables uniform spraying of the detergent, and ensures that every part of the fuel system can be thoroughly cleaned. Compared with traditional spray bottles, empty metal spray cans can effectively reduce waste during the spraying process and ensure the accuracy and efficiency of each spray.

Environmental protection and sustainability

The production process of empty metal spray cans strictly follows environmental protection standards and uses materials that meet international environmental protection requirements, which not only reduces pollution to the environment, but also meets the current market demand for green and sustainable products. Its recyclable characteristics make it a more environmentally friendly choice.

Diversified customization services

This product supports LOGO customization according to customer needs, and uses CMYK offset printing technology for exquisite printing. Customers can customize personalized spray bottles according to brand image. Whether in terms of appearance design or functionality, empty metal spray cans can meet the needs of different customers and provide more choices for brand building.

Looking for a trusted metal packaging manufacturer in China? DKtinplate provides a one-stop service for high-quality tinplate packaging, aerosol cans, and metal printing. Equipped with state-of-the-art machinery and ISO9001 certification, our factory ensures consistent quality and efficient production at competitive prices. We offer customizable designs, wholesale purchasing options, and attractive discounts to meet your business needs. Contact DKtinplate today for affordable prices, promotional offers, and a reliable supply chain for your packaging requirements.