Specification of Tinplate Bottom Ends For Metal Chemical Tanks:

Product Name | Tinplate Bottom Ends For Metal Chemical Tanks: |

Material | tin/tinplate |

Usage | packaging for paint,coating,oil,thinner,hardener and other chemicals |

Shape | Round shape |

Dimension | 298*275*445mm |

Thickness | 0.32mm,0.35mm,0.38mm |

Capacity | 25 liters |

Printing | CMYK 4C printing,customized printing |

Certificates | ISO 9001,UN approved |

Packing | Stack one by one,outside plastic bag,then pallet packing |

Delivery time | Within 20~30 days |

Coating on bottom: 2 layer of gold oil coating on bottom

Composition of tinplate:

Tinplate is mainly composed of five parts: steel substrate, tin-iron alloy layer, tin layer, oxide film and oil film.

Name | thickness | composition | properties |

oil film | 2~5mg/cm² | Cottonseed oil or malonic acid diester | Lubrication and rust prevention |

oxide film | 1~3mg/cm² (Single-side coating) | Ferrous oxide, tin oxide, chromium oxide, metallic chromium | After chemical treatment, it has the functions of anti-rust, discoloration and anti-sulfide |

tin layer | 5.6~22.4mg/cm² | Pure tin | Beautiful, easy to weld, corrosion-resistant and non-toxic |

tin-iron alloy layer | <1g/cm² | Tin-iron alloy crystals | Corrosion resistance, but too thick for poor processability and solderability |

steel substrate | 0.2~0.3mm | Low-carbon steel | Good processing performance, with certain strength after can making |

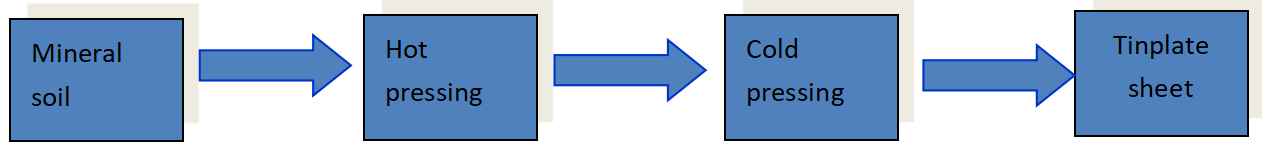

Tinplate raw material comes from:

(1) Iron ore is produced in Australia and Brazil.

(2) Approximately 1 ton of tinpate sheet can be extracted from 1.8 ton of iron ore.

Application:

From packaging materials for food and beverages to grease cans, chemical cans, and other miscellaneous cans, the advantages and characteristics of tinplate provide good physical and chemical protection of the contents.

Introduction of Tinplate Bottom Ends:

The metal material of the three-piece tin body is tinplate. The metal packaging material for the top and bottom covers can be tinplate, chrome-plated iron, and aluminum. In addition to aluminum, it will not rust. Tinplate and chrome will rust when exposed to wet environments. The use can isolate the contact between metal materials and the outside world, avoid abrasion of the metal substrate, and prevent the corrosion of the substrate by the corrosion factors in the food.

Features of Tinplate Bottom Ends:

1. Tinplate bottom ends are non-toxic and harmless. The composition does not contain any toxic and harmful substances, and can reach a high level of hygiene. It fully meets the requirements for the use of food packaging materials and can directly contact food.

2. Tinplate bottom ends have good tightness, which can ensure that the packaging can is completely sealed when in use. This can not only prevent liquid food from leaking, but also can prevent food from contacting with the outside world and ensure food quality.

3. Tinplate bottom ends can be used in food packaging cans, and because they have very good light-shielding properties, they can block the penetration of light and prevent food quality from being affected by light irradiation.

4. tinplate has high strength and good formability. While it can be made into bottom ends of various shapes, it can also maintain a stable structure during use. It can be reliably sealed when used in food packaging cans and can be long Time to use.