Specification of Prime Tin Plate For Toys:

Thickness | 0.18~0.40mm |

Width | 500~1000mm |

Material | MR SPCC |

Tin Coating | 1.1/1.1, 2.8/2.8/,5.6/5.6 |

Temper | T2~T4 |

Coil Weight | 3~10 MT |

Oiling | DOS |

Surface Finish | Bright, Stone, Silver, Matt |

Annealing | CA, BA |

Packing | Wrapped completely with an inner cover of plasticor water proof papers with corners pertected |

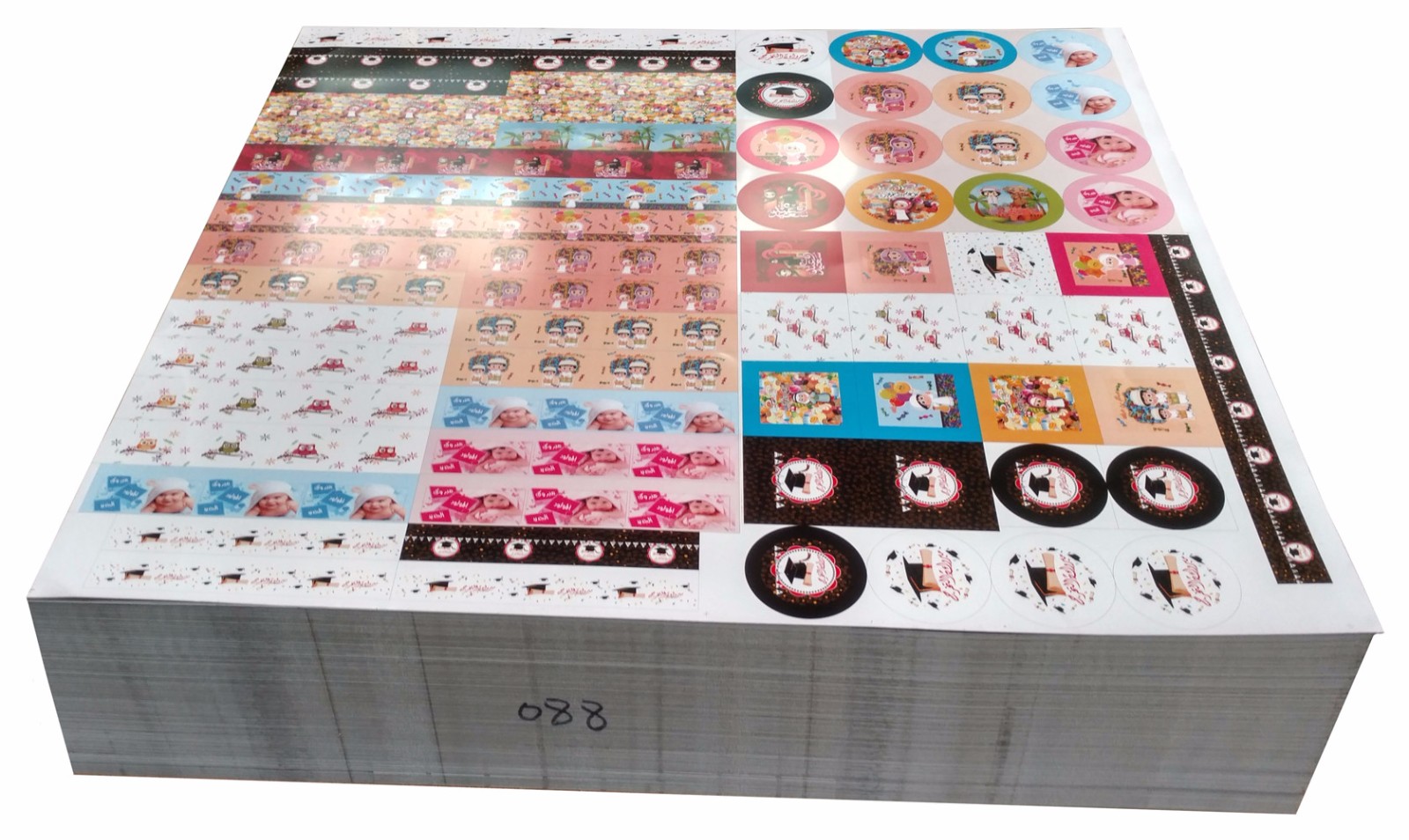

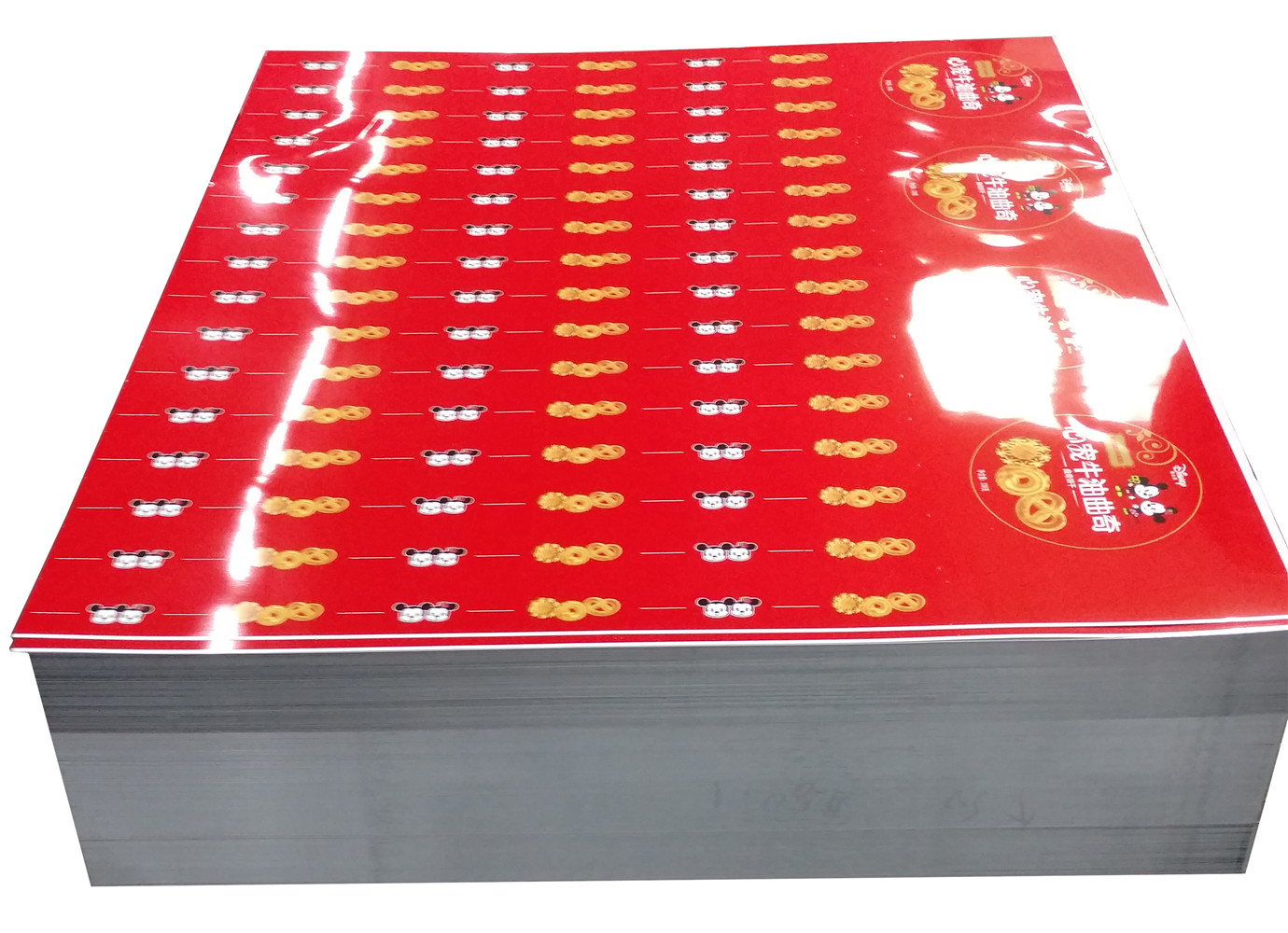

Tinplate Printing For Toys

Printed Tinplate

Printing Tin Plate

Tinplate

Tin plate performance:

Mechanical properties. The mechanical properties of tinplate mainly refer to the mechanical properties of the steel substrate, including mechanical properties (tempering) and forming properties (cup burst value). The tempering degree is the hardness. The comprehensive mechanical properties of tin plate are generally described by tempering degrees. The tempering degree of tin plate is expressed by the surface Rockwell hardness value HR30T, and the symbol is formed by T plus a number. Different national standards have different expression methods for hardness.

Code | Rockwell hardness scale(HR-30T) | Application | |

Single Reduce (SR) | T1 | 46~52 | Deep-drawn cans or nozzles with special processing properties.etc. |

T2 | 50~56 | Medium deep-drawn cans, such as small square cans, oval cans, etc. | |

T2.5 | 52~58 | Hardness between T2 and T3, such as small can body, can lid. | |

T3:T3CA | 54~60 | Generally empty can body, can lid or crown cap. | |

T4CA | 58~64 | Can body or crown cap with slightly higher hardness than T3. | |

T5CA | 62~68 | Can body or can lid for large cans , and for containers with high internal pressure. | |

Double Reduce (DR) | DR-8 | 70~76 | Can lid for beer and carbonated drinks |

DR-9 | 73~79 | Can body or can lid and tray for large cans, | |

DR-9M | 74~80 | Can lid and tray for beer and carbonated drinks | |

DR-10 | 77~83 | Can lid and tray for beer and carbonated drinks | |

Note:

1. The specification mark CA is a continuous annealed tinplate, which has the advantages of high hardness, uniform mechanical properties, high corrosion resistance, and is suitable for high-speed can making.

2. DR-8, DR-9, DR-10: the annealed tinplate are rolled into extremely thin and strong tinplate.

3. Continuous annealing and DR tinplate have mechanical directionality, so when used to manufacture can bodies, the rolling direction must be parallel to the circumference of the empty can.

Origin of tin plate:

Tin plate originated in Bohemia (today in the Czech Republic and Slovakia). Since ancient times, this place has been rich in metal, advanced technology, and knows how to use water power to engage in machine manufacturing. It has been producing tin plate since the 14th century. Later in the First World War, a large number of tin containers (cans) were made by the military of various countries and are still used today.

Application of tin plate:

① It is widely used in the canning industry to make cans, tins, boxes for packaging cosmetics, candy, biscuits, tea, milk powder, etc.

② It is a good capping material for glass, plastic and other bottles.

③Tinplate has versatile applications, including the making of toys like tinplate cars and trucks.

Main markets:

Our tin plates are mainly exported to USA, Egypt, UK, Russia, Germany, Myanmar, Canada, Malaysia, Argentina, Peru, Colombia, Saudi Arabia, UAE, and so on.