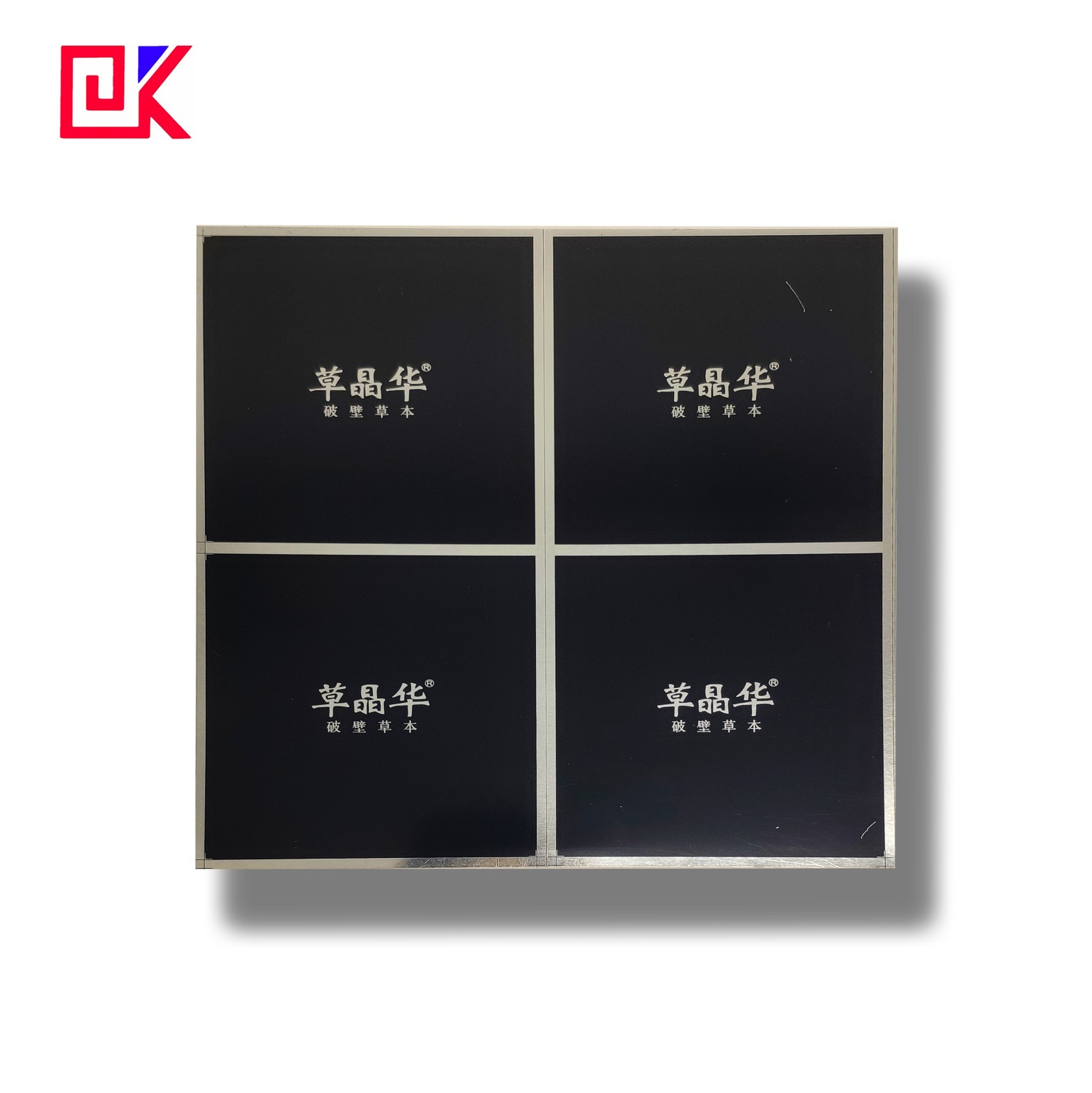

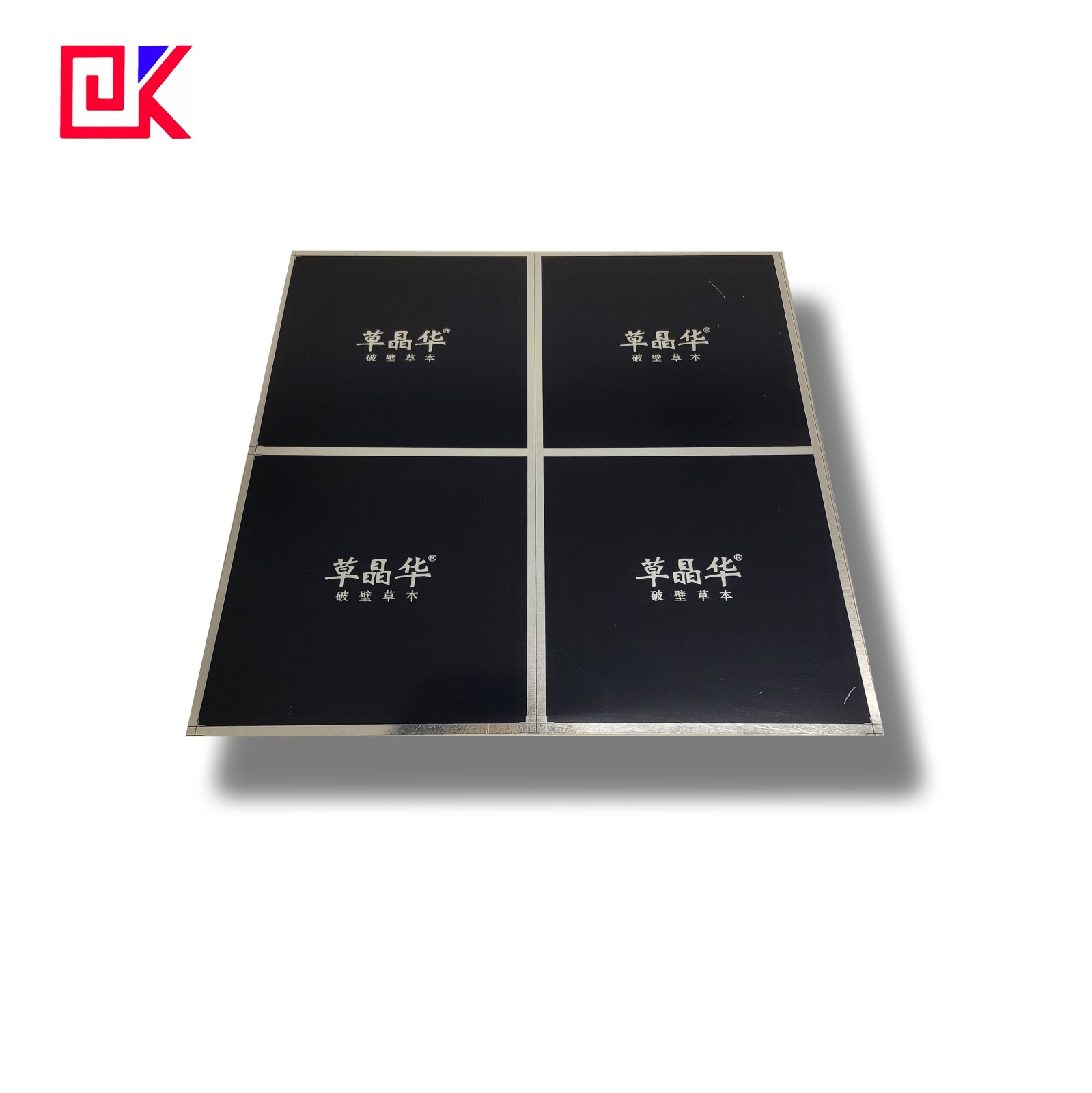

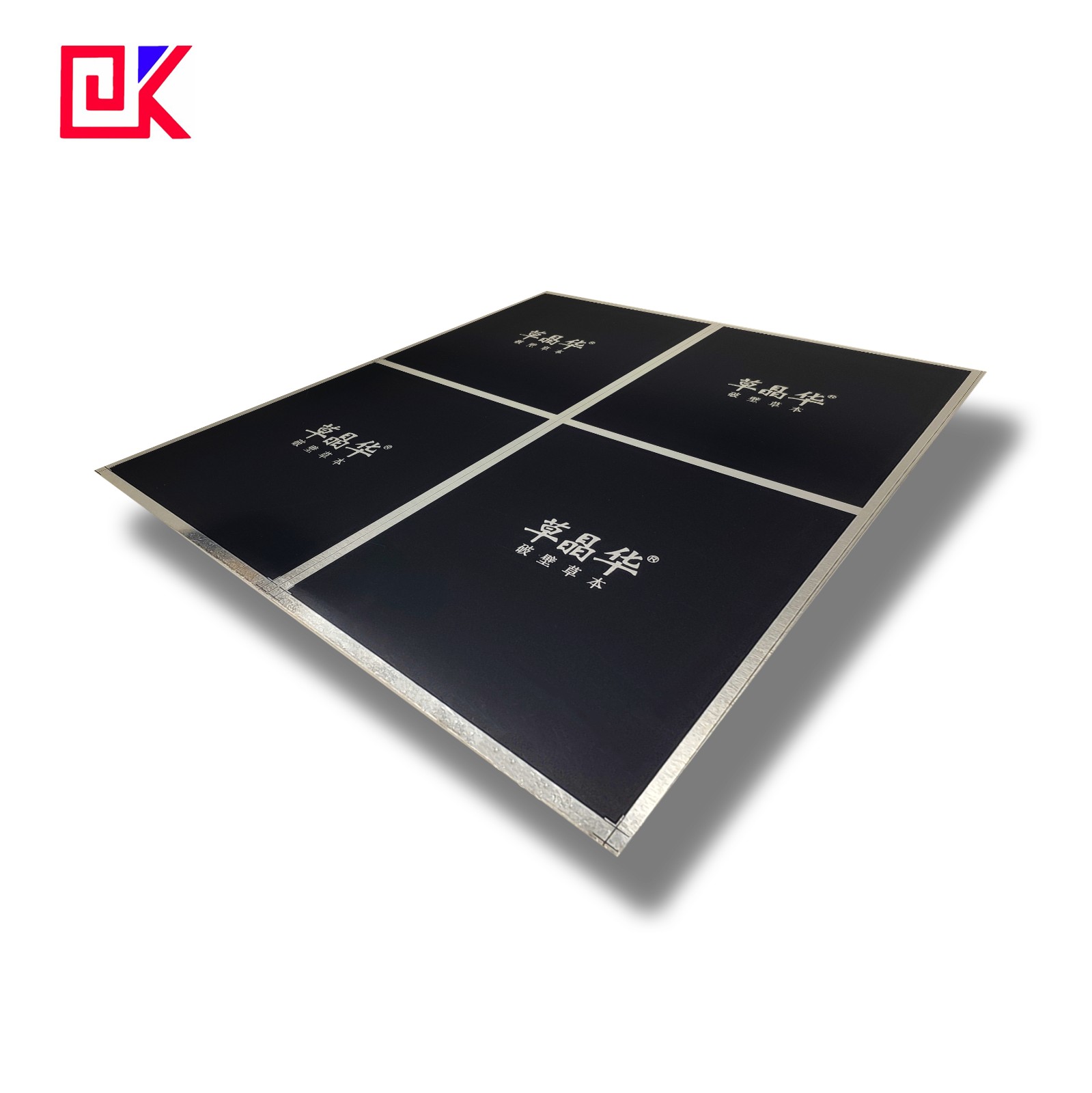

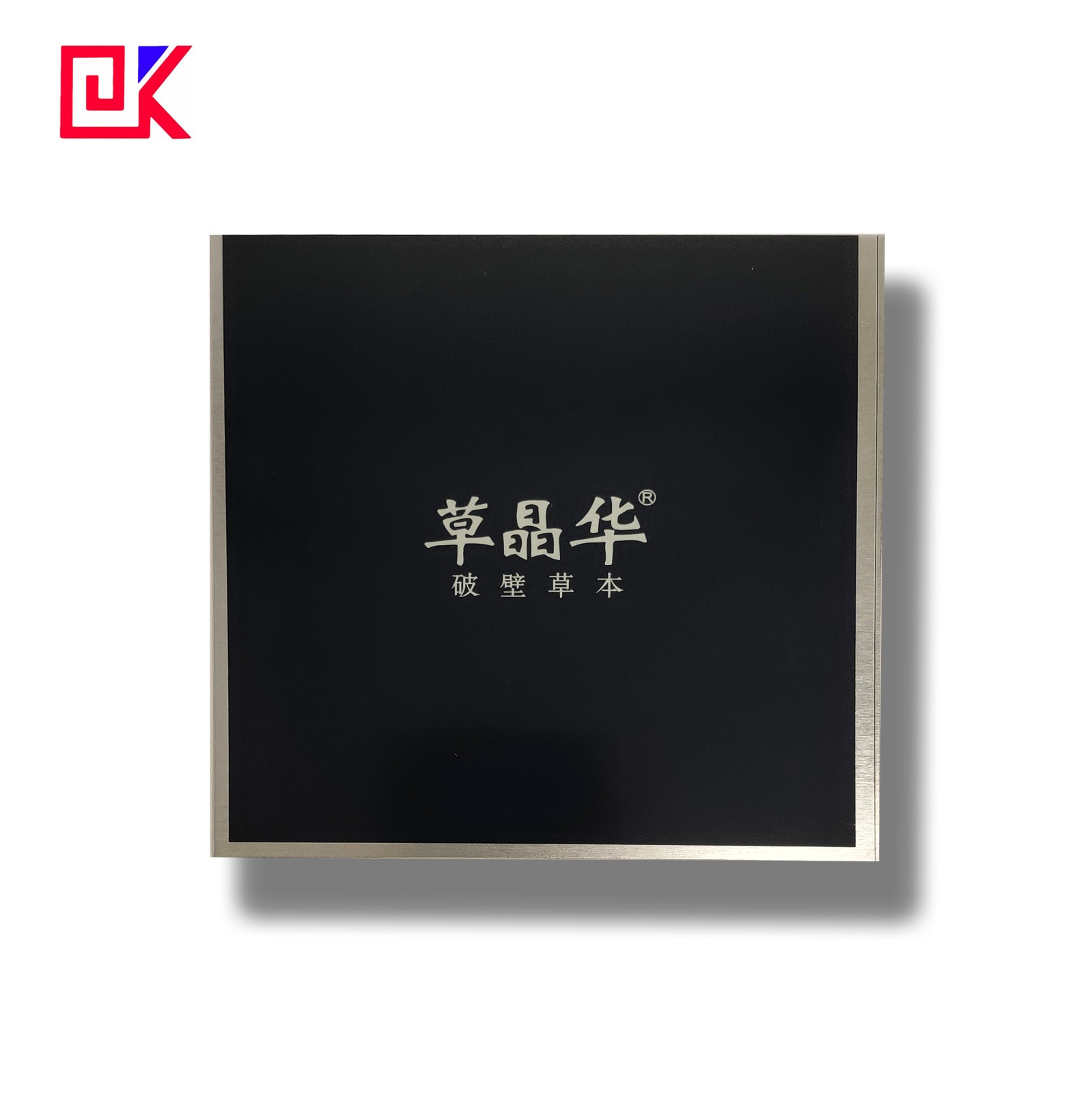

Specification of CMYK Offset Printing Tinplate For Tin Box:

Product name | CMYK Offset Printing Tinplate For Tin Box |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA,CA |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.15~0.45mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

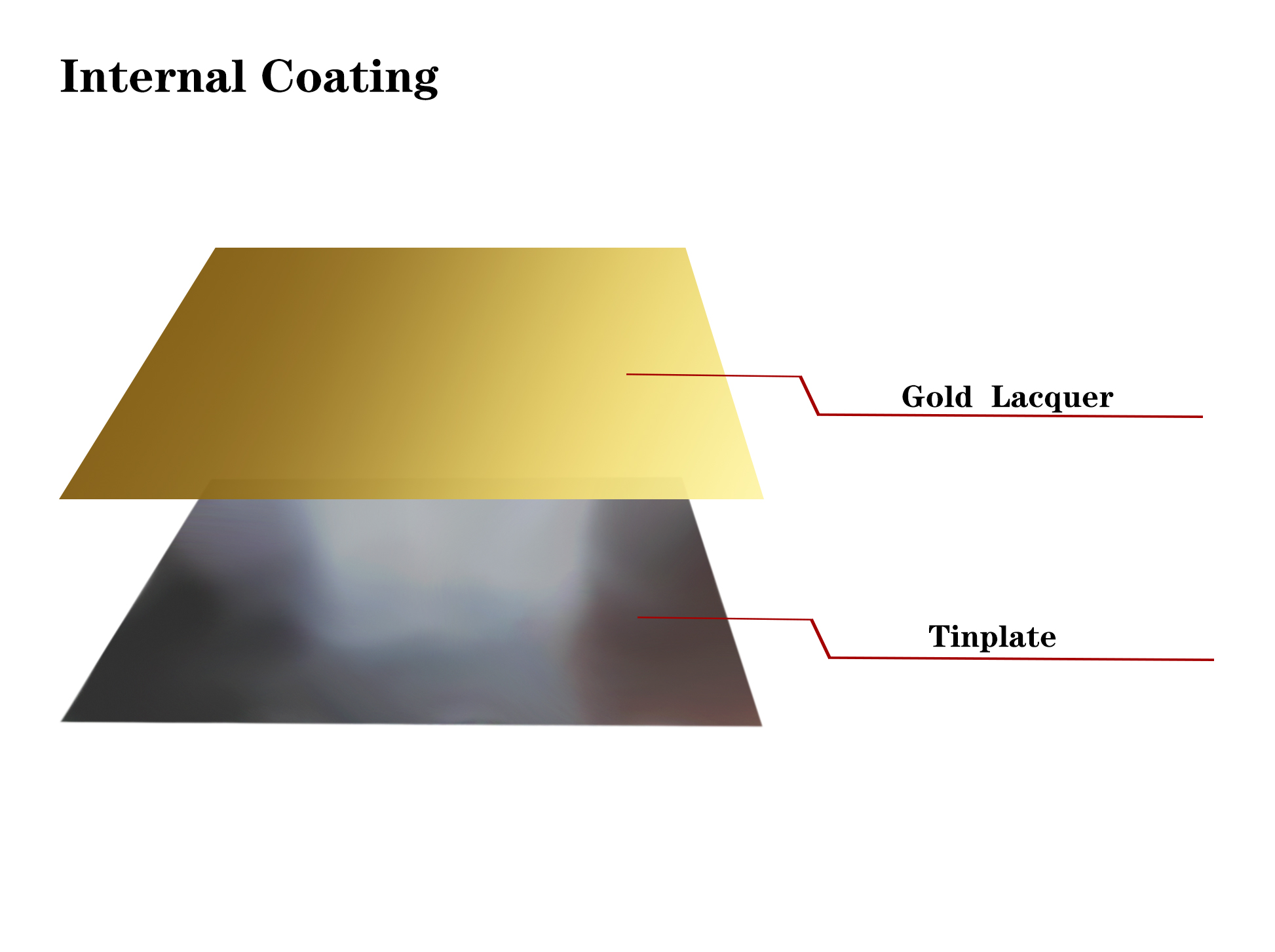

Internal coating | White coation or Gold lacquer |

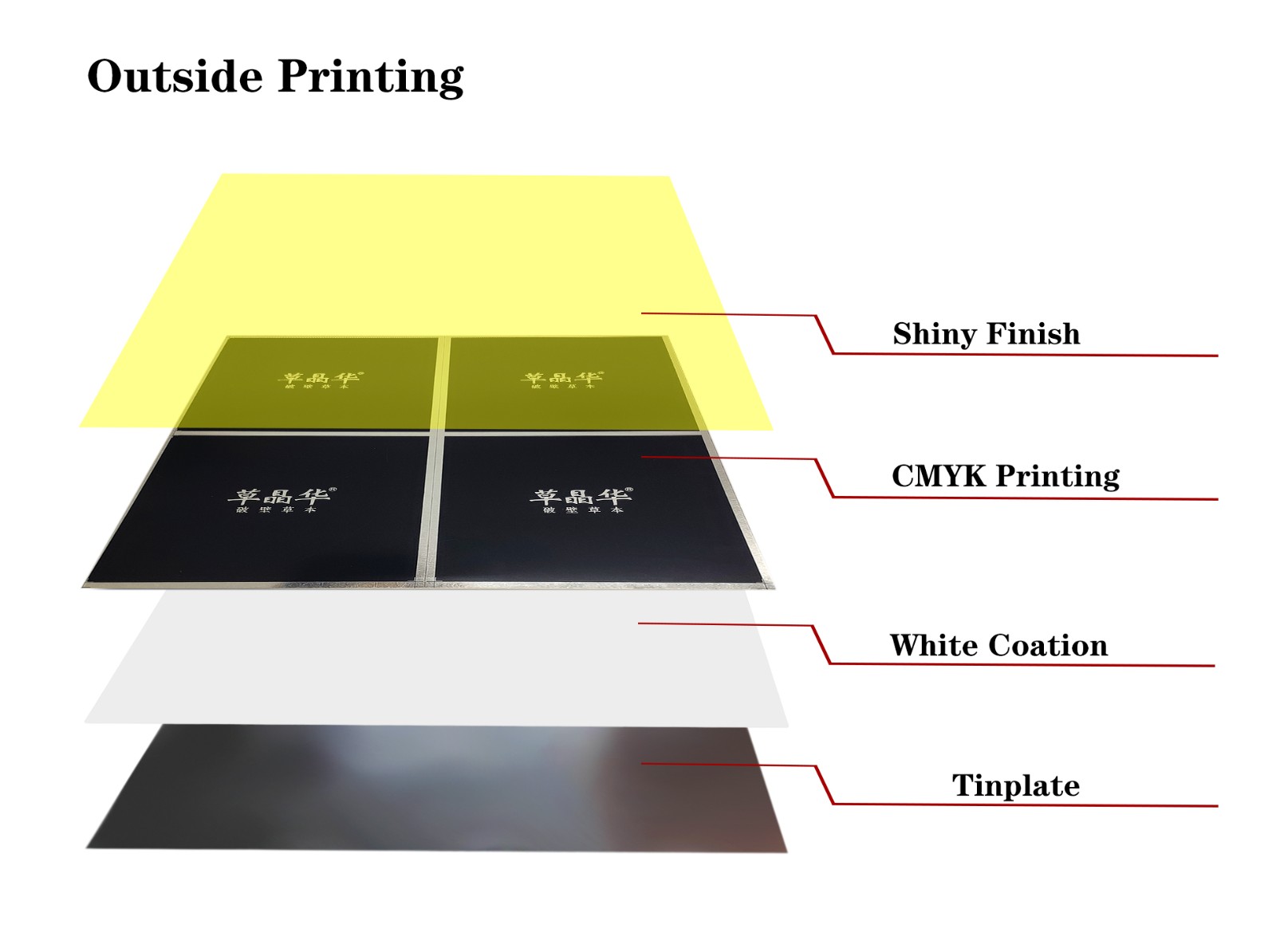

Outside printing | White coation+CMYK Printing+Shiny finish |

Application | For any packing Tin, Box, Can, Bucket, etc(Food, oil, medicines, cosmetics, perfume,toys, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 4000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

Standard of tinplate Temper:

Standard Material | Q/BQB 455-2009 | JIS G3315-2008 | ASTM A623M-08 | EM 10202:1989 | EN 1020:2001 | ISO 11950:1995 |

Single Reduce | - | T-1 | T-1(49) | T50 | TS230 | TH50+CE |

T-1.5 | - | - | - | - | - | |

T-2 | T-2 | T-2(T53) | T52 | TS245 | TH52+CE | |

T-2.5 | T-2.5 | - | - | TS260 | TH55+CE | |

T-3 | T-3 | T-3(T57) | T57 | TS275 | TH57+CE | |

T-3.5 | - | - | - | TS290 | - | |

T-4 | T-4 | T-4(T61) | T61 | TH415 | TH61+CE | |

T-5 | T-5 | T-5(T65) | T65 | TH435 | TH65+CE | |

Double Reduce | DR-7M | - | DR-7.5 | - | TH520 | - |

DR-8 | LR-8 | DR-8 | DR550 | TH550 | TH550+CE | |

DR-8M | - | DR-8.5 | - | TH580 | TH580+CE | |

DR-9 | DR-9 | DR-9 | DR620 | TH620 | TH620+CE | |

DR-9M | DR-9M | DR-9.5 | DR-660 | - | TH660+CE | |

DR-10 | DR-10 | - | - | - | TH690+CE |

Tinplate raw material comes from:

(1) Iron ore is produced in Australia and Brazil

(2) Approximately 1 ton of metal tinplate can be extracted from 1.8 ton of iron ore.

Our advantage:

1). Our product quality is strictly guaranteed!

2). We can provide best service!

3). Our price is competitive!

4). We have more than 10,000 tons in stock so that can

Arrange production schedule immediately for customers.

5). We can do good payment terms.

What is the process and characteristics of CMYK Offset Printing Tinplate?

The process of CMYK Offset Printing Tinplate is as follows: plate making-coating treatment before printing-printing-varnishing.

(1) Plate making process requirements.

The photographic plate making of printed iron is basically the same as the photo plate making in general printing, and has special requirements for the characteristics of tinplate printing.

① Use the ideal screen to ensure good reproduction of the tone. Due to the characteristics of halftone dot copying, in the iron sheet printing, the dark tone and halftone areas have two extremely obvious tone jumps, the halftone jump level of the printed matter becomes deeper, and the dark tone changes sharply, especially with the square dot screen.

② Reduce the number of colors and use standard three-primary color process to copy and print.

Multi-color printing increases the number of overprints, is prone to overprinting, friction damage, etc., and consumes man-hours and raw materials, which increases costs. The product has a long production cycle, colorful colors, and many defective products.

It is an ideal reproduction process to replace the special color and auxiliary color of the multi-color version with the standard three primary color process.

③ The application of the white version is essential in printing iron. Print the iron sheet in white before you can print a beautiful pattern on it. Generally, the printing iron is full-printed white, but when there is gold printing, pay attention that the white cannot be padded under the gold, otherwise the striking effect of gold cannot be achieved.

④Because it is processed and formed after printing iron, it is necessary to leave a bite or weld when making a plate. In the case of considering the bite and weld, the pattern must be centered, otherwise the pattern will easily cause the pattern to deviate from the center, especially for square barrels.

(2) coating treatment before printing.

Remove the dirt on the front and back of the tinplate sheet before applying the base. The coating treatment is divided into inner coating and outer coating.

① Inner coating refers to the inside of the iron sheet, that is, the inner side of the iron sheet molding product, that is, the side that is in direct contact with the contents, and a layer of protective varnish is applied to protect the iron sheet from the contents and protect the contents .

If food cans are made, the inner coating is in direct contact with food, which is required to be non-toxic, odorless, and not to react chemically with the contents. After internal coating, it should be dried in a desiccator.

② Overcoating (priming) refers to coating or printing a layer of white ink on the outside of the iron sheet, that is, the printing surface, to cover areas where metallic luster is not needed, so that the colors printed on white are more vivid.

(2) tinplate printing process.

① Printing machine. tinplate printing machines mainly include platform and rotary offset printing machines.

Ⅰ. The platform offset press uses manual refilling, which has a low production efficiency and a small printed sheet size.

Ⅱ. The two-color machine is the main model of the rotary machine, but because the iron sheet is non-absorptive, multi-color printing cannot be performed, and only two-color printing can be performed on the screen with less overlap.

② drying device. The iron sheet material is non-absorptive. It is wet after being coated or printed or coated. It must be dried in a dryer. There are two types of drying devices: heating and drying and ultraviolet irradiation curing devices.

Ⅰ. The heating temperature and drying time of heating and drying affect the drying effect and the quality of printed matter.

Ⅱ. UV curing ink must be used for UV irradiation.

③ Printing ink. Because the iron sheet is not absorbent, and the printed iron sheet needs to be processed and processed, the printing ink should have different characteristics from ordinary offset printing inks.

Ⅰ. Dryness and heat resistance of the ink: The ink film of the printing ink needs to be heated and dried, so the white ink after heating is required not to change color and yellow, the color ink does not fade and discolor, and the varnish does not lose light.

Ⅱ. Solvent resistance of inks: The printed varnish contains various solvents. In order to prevent bleeding during varnishing, the ink should have good solvent resistance.

Ⅲ. the retort resistance of the ink.

Ⅳ. the processing resistance of the ink. Most of the printed iron products need to be processed by stamping, punching, bending, closing, etc. Therefore, the ink film on the surface of the iron sheet should have a strong structure, and it should not fall off or be damaged during and after processing.

Ⅴ. light resistance and weather resistance of the ink. Various daily necessities are generally stored for a long time, so it is required that the printed iron inks cannot fade and age due to light exposure or weather factors.

(3) Polishing process.

After the tinplate sheet is printed, it is necessary to apply bright varnish, the purpose is to protect the screen ink film, increase the gloss of the printed matter, and make the product more beautiful.